Brake system: Parts and installation

Here you get an overview of how a brake system works and what parts are included.

The different parts are divided into categories as shown below. These headings together give an image of which parts can be used and whether an upgrade is necessary or not.

The different parts of the car's braking system are.

- Pedal box / Brake pedal

- Brake sensor

- Brake servo / booster

- ABS unit

- Brake cylinder

- Brake fluid reservoir

- Brake fluid

- Handbrake / Hydraulic handbrake

- Brake caliper

- Brake caliper adapter

- Brake disc

- Brake pads

- Brake cooling

- Brake distribution valve

- Bias bar

- Brake reducer/ Brake lock

- Brake hose/ tube/ fittings

- Bleed brakes

1 ▼

Pedal box / Brake pedal

The function of a pedal box / brake pedal is to get a power exchange so that you become strong. You have a ratio of 5:1 to 7:1 approximately. This means that if a pedal box has a 7:1 ratio and you put a 10kg load on the brake pedal, 70 kg is placed on the master brake cylinder (7x10). If a brake servo is used, not as much power or pedal ratio is needed as without a brake servo.

The original pedal box / prake pedal is usually mounted hanging. In the aftermarket there are also floor-mounted pedal stands.

The pedal rack is connected to the master brake cylinder, brake sensor, brake fluid reservoir and brake servo, which we will discuss in more detail below.

Aftermarket pedal racks usually have a so-called brake balance / bias bar that allow two brake cylinders and thus adjustment of the braking force between the rear and front brakes to be made. By adjusting the braking force / balance between the rear and front wheels, a shorter stopping distance can be achieved and this is something you want when racing. Even a brake reduction valve can achieve the same result, but this instead reduces the power to a pair of brakes instead of distributing the power as a brake bias bar.

2 ▼

Brake sensor

When a car brakes, a sensor is affected which sends a signal that the brake light should be switched on. With this signal, other things can also be controlled with an aftermarket control system (ECU).

This switch / sensor can be mounted directly on the brake pedal but can also be mounted on e.g. the master brake cylinder so a signal is sent when pressure in the brake circuit increases.

3 ▼

Brake servo / booster

A brake servo 7 brake booster amplifies the braking force from the brake pedal to the master brake cylinder. Brake servo is a large vacuum bell that is mounted between the brake pedal and brake cylinder on most original cars. This is then connected with a hose to the engine's intake. When you brake and let off the gas, the engine creates a vacuum. With this vacuum, the brake servo with the help of a membrane sucks itself together and helps create power to the master brake cylinder.

A check valve is mounted on the hose between the engine and the brake servo. This is so that only vacuum and not pressure can reach the servo. It is important that the hose is reinforced and can withstand vacuum properly.

4 ▼

ABS unit

A car with ABS has a so-called ABS unit installed. This device allows you to brake max without locking the brakes. Because this unit pulses the braking force so that the brakes do not lock, you can steer the car. Without brake servo, the brakes can lock during hard braking and then you cannot steer the car.

Original ABS is almost always fitted to cars. In the aftermarket, especially when racing, this is disconnected as it is not adapted for racing. There are ABS units for racing but this is not that common.

Since original cars with ABS have a so-called two-circuit system, the ABS unit has two inputs from the master brake cylinder and 4 outputs, one for each wheel. In this way, each wheel can be adjusted separately using a connected ABS control unit (ECU)

5 ▼

Brake cylinder

A master brake cylinder transmits the force coming from the brake pedal through brake lines out to the brake caliper. In addition to being able to adjust the braking force with the pedal box ratio, you can also adjust the force required to brake the car with the hydraulic ratio.

Two-circuit system means that the brake system has two separate hydraulic circuits, originally the left front and right rear wheels are usually connected in one circuit and vice versa in the other circuit. With an aftermarket pedal box and brake bias bar, the front and rear wheel pairs are instead connected. This is to always have braking power even if a circuit is broken.

Original master brake cylinder has two separate circuits in the same cylinder = two outputs.

Aftermarket brake cylinders usually only have one circuit, but then you instead use a brake balance bar / bias bar together with two master brake cylinders, one to the rear and one to the front.

A brake cylinder has a connection for the inlet of brake fluid from the brake fluid reservoir. This system is not pressurized but only self-flowing and therefore the container must be mounted over the cylinder. In addition to the inlet, there are one or two outlets towards the brake caliper. This is the pressure side and here it is important that assembly is done correctly as the braking force can be completely lost if it is connected incorrectly.

Brake cylinders are available with integrated reservoir and for external reservoir. In addition to pushing cylinders, there are pulling brake cylinders. Which cylinder is used depends entirely on the design of the pedal box and the installation.

Smaller brake cylinder = less pedal force for a given force at the brake caliper = longer pedal travel.

Larger brake cylinder = more pedal force for a given force at the brake caliper = shorter pedal travel.

6 ▼

Brake fluid reservoir

A brake fluid reservoir supplies one or more brake cylinders with brake fluid. Original, this is often mounted directly on the cylinder, it can look like this in the aftermarket as well, but usually external containers are used.

A lid for filling and one or two exits is the only thing used. There may be an extra outlet that supplies the clutch master cylinder with fluid. There are outlets for hose connection or threaded connections.

7 ▼

Brake fluid

Special hydraulic fluid called brake fluid is used in brake systems. This is because it takes care of internal gaskets and is not compressed at high pressures. Over time, the brake fluid absorbs moisture, which can be compressed at high pressure and then the brake pedal feels spongy. Therefore, the fluid should be changed at regular intervals, preferably every year. -More often in racing.

Original brake fluid has properties for long service intervals, but cannot withstand as high heat during hard driving where brake pads emit extra heat radiation. Performance brake fluid for the aftermarket instead has properties for high heat / boiling point and instead needs to be changed more often.

Different variants of brake fluid and DOT classification can be read more about here.

DOT5 - Silicone-based brake fluid = non-hygroscopic = not used in today's cars.

If this is to be used, check carefully that all gaskets and the system in general can handle this.

8 ▼

Handbrake / Hydraulic handbrake

The function of a handbrake is to keep the car still when parking. The classic handbrake activates the rear brakes through a handbrake cable. Now, an electric handbrake and brake caliper with an electric motor are increasingly used.

In racing / aftermarket, there are handbrakes that are connected to the rear brake circuit. This is called a hydraulic handbrake. This type of brake works just like the brake pedal that activates a brake master cylinder. This is not used to keep the car still for a long time, it is mainly for drifting and rally. This is also not approved for use on the street, then the original handbrake system must also be used.

A hydraulic handbrake can be fitted in series between the brake pedal and the rear brakes but a distribution valve is recommended when installing it. Just like the footbrake, the handbrake can have different ratios to adjust the force required to lock the rear wheels. There are also different variants of handbrakes where the master cylinder is mounted forward / to the rear of the hand brake or separately with an extended push rod.

A hydraulic handbrake must not be used as a parking brake for a longer time (1h +) as the system lose pressure

9 ▼

Brake caliper

A brake caliper has the task of pressing the brake pads together over the brake disc with the force that the driver applies through the brake pedal. In this way, friction is created between the brake disc and the brake pads so that the car can be stopped.

Brake calipers can be mounted anywhere around the brake disc using caliper adapters. Depending on the construction and intention, the position is determined and this can vary. Sometimes the caliper is mounted in front of the brake disc and sometimes behind it. In the past, brake calipers with a piston have been most common. Now more, a variety of mounts, number of pistons and type of clipers are used to optimize brake performance, safety and durability. More pistons on an original car can mean longer service intervals, while more pistons on a performance car can mean even clamping force and thus more effective braking.

A caliper has an air nipple mounted at the top, sometimes two nipples if the caliper is split in two with pistons on each side. There is no output on the brake caliper, but only an input as the brake fluid that is pushed forward returns again when the brake pedal is released back to normal.

10 ▼

Brake caliper adapter

An original brake caliper often has a brake caliper adapter that attaches to the spindle. This is to keep the caliper in place and centered to the brake disc. Brake caliper adapter is, in other words, a bracket for brake calipers.

It is common for brake calipers to be changed / upgraded and then you need an adapter, a bracket to mount the brake caliper on the car's spindle. There are many ready-made variants to choose from that fit popular brake calipers and enable installation on other car models than what was originally intended.

A caliper adapter / brake clamp / caliper mount is simply fitted with bolts between the caliper and spindle to hold the caliper in place.

There are variants for double brake calipers where one is for the footbrake and one for the handbrake.

11 ▼

Brake disc

A brake disc is part of the car's braking system and together with brake calipers and brake pads, you can stop the car. Original, the diameter and thickness of the brake disc is calculated based on the car's weight and power. In the aftermarket or when racing, you often want a brake disc that has a larger diameter and thickness. These two parameters provide benefits that improve brake performance.

Larger diameter gives better leverage and thus better braking performance. Larger diameter and thickness also provide greater mass that can store more heat and thus provide cooler brakes. This in turn gives better service life to the brakes.

Some things that differentiate different brake discs are:

- Diameter

- Thickness

- Offset

- Bolt pattern / center hole

- Cooling / sensitive to direction of rotation

- Handbrake shoes

- Slots / Drilled holes

- Loose hubs and friction surface

- Material

12 ▼

Brake pads

Brake pads are part of the car's braking system and together with brake calipers and brake discs, you can stop the car. Original brake pads are made to have good initial bite / high friction but they do not withstand heat very well. Therefore, original brake pads can "go bad" after just one or a few hard brakes when the temperature exceeds what the pads can handle.

In the aftermarket / performance, there are brake pads that can withstand significantly higher temperatures in order to be used during hard driving and racing. What is happening now is that the brake performance at cold / low temperature is not as good as with the oem pads. You therefore have to worm them a bit so that the brake pads reach a certain temperature before they reach their full potential.

Different types of brake materials are available and these are well suited to different areas of use.

13 ▼

Brake cooling

Both brake pads, brake calipers and brake discs can withstand high temperatures, but regardless of which materials are used to withstand high or extreme temperatures, brake cooling is a good solution to cool the brakes and keep brake performance at its peak.

Brake discs often have built-in cooling as standard in the form of a fan-like pattern between the friction surfaces. But often it is good to supplement with extra cooling / ventilation to remove the highest temperature peaks. This is done by directing cold air from the front of the car to the front brakes. Different solutions are available but at least you should lead air from the front to the brakes so the air in the wheel around the brakes is replaced faster with new cooler air.

It is enough to point the hose towards the brakes, but more advanced solutions include the brake shield, which has a connection for a hose that draws cold air from the front of the car. Regardless of how you choose to do it, supplying air to the brakes is a good solution. - so-called brake cooling.

14 ▼

Brake distribution valve

A handbrake can be engaged in two ways.

- In series to the rear circuit of the brake system.

- With the help of a brake distribution valve, the safety of the brake system can be maintained.

A hydraulic handbrake is connected to the hydraulic brake system and should be connected through a brake distribution valve. In this way, the footbrake and handbrake are separated, even though they are connected to the same circuit. This prevents the brakes from locking and safety is maintained.

The installation requires more connections / fittings and there is more to think about, but the end result is better and safer than if the handbrake is connected in series on the rear brake circuit.

The brake system and distribution valve are sensitive to dirt. Dirt in the brake system destroys internal gaskets over time, while the distribution valve shows symptoms directly by e.g. binding. This is good as you immediately get an indication of dirt in the system!

15 ▼

Bias bar

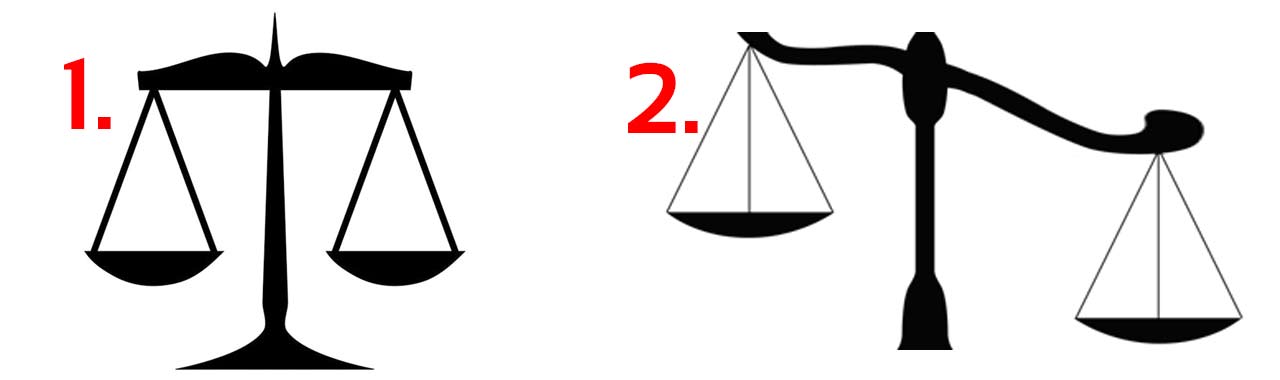

Brake bias bar is exactly as it sounds, a bias bar that distributes the braking force between the rear and front brakes. Think of it as a swing with equal weight at both ends (1). If the axis is in the middle, the swing is in scale. But if the pivot point is moved just a little bit in one direction, the force changes between the different sides (2). This is how you adjust the braking force between the rear and front brakes with the help of the brake bias bar.

For this to work, two master brake cylinders are needed, one for the front brake and one for the rear brake. When the brake balance is adjusted, the axis in the middle changes (similar to the scale in picture 1 and 2.) and force is distributed differently between the two brake cylinders.

To clarify this further, you can say that the two scales are brake cylinders and the shaft in the middle is the brake pedal on which the scale balances.

There is only one known type of brake balance / brake bias bar but the design and model may differ.

16 ▼

Brake reducer / Brake lock

A reduction or locking mechanism added to the braking system is used to adjust how much braking force is to be distributed or to be completely removed to the calipers. Depending on where these valves are mounted, braking power can be reduced / removed on that particular circuit. If the valve is mounted on the front circuit, the pressure can be adjusted or completely removed on the front circuit with the back circuit unaffected. This also applies if the valve is only mounted on the back circuit.

Brake adjustment / reducer

A brake adjustment has a turkning knop or lever that can be adjusted freely or in steps so that all or only a certain amount of pressure reaches the brakes. If a brake bias bar is not used, this type of reduction can instead be used on the circuit that should not have as much braking force, often the front. This valve can also be used if the rear brakes have too much braking power and wants to lock.

Brake lock

If a brake lock is used, the pressure can be completely shut off. This is done in e.g. drag racing if the rear tires are to be heated. Then brake pressure can be completely disconnected from the rear wheels so they can spin while the front brakes have full brake pressure.

Both of these types have an input from the brake pedal and an output to the brake caliper. They are connected in series with the brake line for front or rear brakes.

17 ▼

Brake hose/ tube/ fittings

Brake pipes, brake hoses and fittings are what connect all the parts in a brake system. Brake pipes are usually used from the master cylinder out to the wheel housing in the areas that are fixed and do not have contact with the car suspension that moves. From there, brake hose is then used which is flexible and can move along with the wheel suspension.

Brake hose

Original rubber brake hoses are used, although these are reinforced, they flex and make the brake pedal feel soft. Rubber ages and can cause problems when the inside releases dirt or swells so that the flow is restricted with uneven braking as a result.

Steel braided brake hose

Often, the original rubber brake hose is replaced by steel braided plastic brake hoses with a steel braid as a cover. This type of hose does not flex so much that it is noticeable and also has such a good service life that cannot be measured by anything else. Therefore, this hose is fitted instead of the original brake hose in the aftermarket and racing.

Brake lines

Brake pipes are available in copper and copper-nickel. Copper-nickel is harder / stiffer than copper and does not need to be clamped as much. It's easier to get these nicely routed. Read more about how you can cone brake pipes in our guides.Connections / fittings

The various connections are called brake nipples, air nipples and compression fittings. These enable pipes and hoses to be threaded into the various brake components and keep tight. Almost exclusively, the following threads are used:

- 3/8" -24

- 7/16" -20

- M10x1

- M12x1

On European and Japanese cars, M10 and M12 are used. On American cars, 3/8" and 7/16" are used. When building aftermarket the most common threads are 3/8" and 7/16" but also M10 and M12 are sometimes used so be aware of this.

In order for the products to seal correctly with fittings, both parts have a taper. One has concave and the other has convex taper.

3/8" and M10 are similar. These are used on the pressure side between the brake cylinder and brake caliper.

7/16" and M12 are used on the low pressure side between reservoir and brake cylinder.

18 ▼

Bleed brakes

You can read more about how to bleed your brake system here, but the basic idea is that the brake lines should not be at the highest point because air easily gets stuck there and is difficult to remove. Air in the brake system makes the brake pedal feel "spongy"

▼

▼

-

Brake system

- Brake system: Parts and installation

- Brake bias bar

- Brake distribution valve installation

- Brake fitting - Convex or concave

- Brake fittings (Video)

- Brake fluid information

- Brake pipe flaring

- Carbotech: Choose the right brake pads

- How to bleed your brakes?

- Master brake cylinder: What size should I have on my master brake cylinder?