ARP Bolts: Material and Specifications

ARP manufactures fasteners from a wide range of materials, from popular stainless steel and 8740 chrome moly to exotic alloys developed to withstand space travel.

You should also know that there are grades within specific alloys. For example, 8740 comes in four grades:

- SDF (guaranteed seamless and defect-free)

- CHQ ("cold head quality")

- Aerospace

- Commercial

ARP uses only the first two (SDF and CHQ), even though they cost more than twice as much as "Aerospace" quality.

The different types of materials discussed are:

- Stainless Steel

- 8740 Chrome Moly

- ARP2000®

- L19

- Aermet®

- Inconel 718

- ARP3.5® (AMS5844)

- Custom Age 625 Plus®

- Titanium

- ARP Grease

- Reusable ARP Bolts

- Torque Specifications

Below, we go through the different grades that ARP uses

1 ▼

Stainless Steel

Stainless Steel: Ideally suited for many automotive and marine applications because stainless steel withstands heat and is practically impervious to rust and corrosion. ARP "Stainless 300" is specially alloyed for extra durability. It is polished using a proprietary process to produce a beautiful finish. Tensile strength is typically estimated at 170,000 psi.

2 ▼

8740 Chrome Moly

8740 Chrome Moly: Until the development of today’s modern alloys, chrome moly was considered a very high-strength material. It is now viewed as a material with moderate strength. 8740 chrome moly is seen as a good ductile steel, with adequate fatigue properties for most racing applications, but only if the threads are rolled after heat treatment, which is standard ARP production practice. Typically, chrome moly is classified as a hardening and tempering steel, which can be heat-treated to provide tensile strengths between 180,000 and 210,000 psi.

3 ▼

ARP2000®

ARP2000®: ARP2000 is an alloyed steel that can be heat-treated to a higher level, resulting in a material with higher strength than 8740. While 8740 and ARP2000 share similar properties, ARP2000 can achieve a clamp load of 220,000 psi. ARP2000 is widely used in racing and drag racing as an upgrade from 8740 chrome moly in both steel and aluminum bolts. Stress corrosion and hydrogen embrittlement are generally not issues, provided that care is taken during installation.

ARP2000 is the most common quality in the aftermarket for cylinder head bolts, main bearing bolts, connecting rod bolts, flywheel bolts, etc.

4 ▼

L19

L19: This is a premium steel that is processed to provide superior strength and fatigue properties. L19 is a very high-strength material compared to 8740 and ARP2000, capable of delivering a clamp load of 260,000 psi. It is primarily used in applications for track racing and drag racing where inertial loads exceed the clamping capacity of ARP2000. Like most high-strength, hardening, and tempering steels, L19 requires special care during manufacturing to avoid hydrogen embrittlement. This material is easily contaminated and susceptible to stress corrosion. It should be stored well-oiled and kept away from moisture.

5 ▼

Aermet®

Aermet®: With a typical tensile strength of 290,000-310,000 psi, Aermet is a new martensitic superalloy that is stronger and less expensive than the superalloy austenitic materials that follow. Because it can achieve incredibly high clamp loads, it is ideal for short but extreme environments such as top fuel, funny car, and certain track racing. Although Aermet is a maraging steel that is vastly superior to other high-strength steels in its resistance to stress corrosion, it must be kept well-oiled and not exposed to moisture.

6 ▼

Inconel 718

Inconel 718: A nickel-based material that falls within the high-temperature superalloy class, it has proven to be equally suitable in lower temperature applications. This material delivers tensile strengths in the range of 210,000-230,000 psi and exhibits improved fatigue properties. Best of all, Inconel 718 is completely immune to hydrogen embrittlement and corrosion.

7 ▼

ARP3.5® (AMS5844)

ARP3.5® (AMS5844): Although similar to Inconel 718, these superalloys are found in many jet engines and aerospace applications where heat and stress threaten the lifespan of critical components. The high cobalt content in this alloy, although costly, provides a material with superior fatigue properties and typical tensile strength in the range of 260,000-280,000 psi. The immunity to hydrogen embrittlement and corrosion in these materials is an important design consideration. These materials are primarily used in connecting rods where extremely high loads, high RPM, and durability are key factors – in Formula 1, NASCAR, and IRL applications.

8 ▼

Custom Age 625 Plus®

Custom Age 625 Plus®: This newly formulated superalloy exhibits superior fatigue cycle life, tensile strength, and toughness – with complete resistance to atmospheric corrosion and oxidation. ARP is the first to develop manufacturing and testing processes for fasteners made with Custom Age 625+. Best of all, it is cheaper and is expected to soon replace MP-35 as the chosen material in the high-strength, superalloy category. Typical tensile strength is 260,000-280,000 psi.

9 ▼

Titanium

Titanium: ARP now offers custom fasteners made from an alloy (Ti6Al-4V) that is specially heat-treated (a process developed by ARP's own Russ Sherman) and provides superior strength compared to other titanium alloys used in racing and aviation. The material has a nominal tensile strength of 180,000 psi and is highly corrosion-resistant. The biggest advantage of titanium is, of course, its weight – which is about 40% lighter than a comparable steel fastener. Cylinder head bolts and accessory bolts are ideal applications for this lightweight material.

10 ▼

ARP Grease

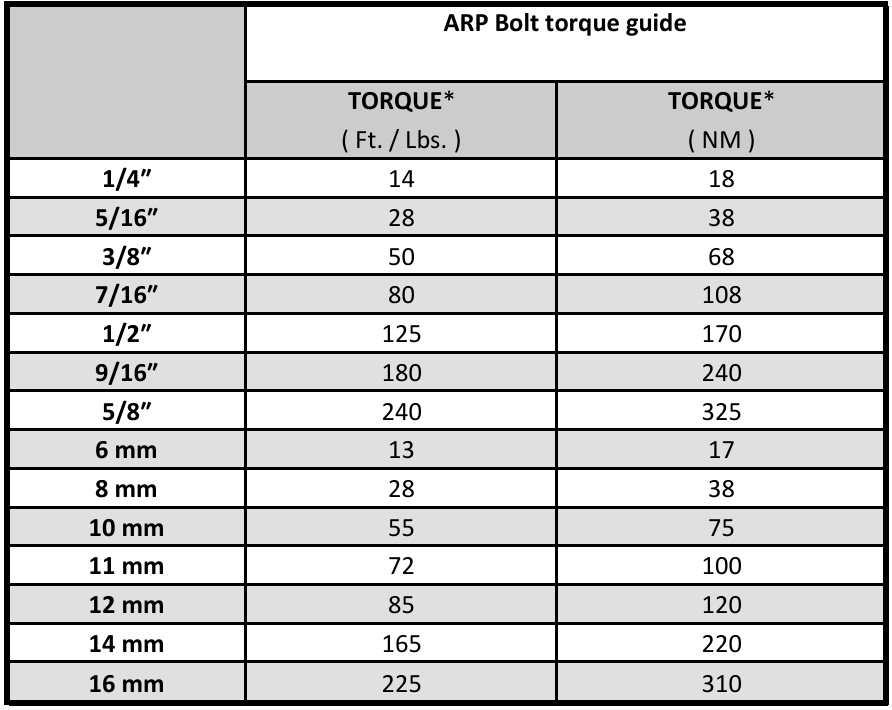

Torque Specifications

The torque specifications given for ARP bolts are with ARP grease. This provides a preload of the bolt within the range of 5%. This is about 4 times better than using regular oil or grease. So always use ARP grease to avoid uneven tightness of the bolts.

Application

ARP grease should be applied to all contact surfaces of a bolt or nut. Under the bolt head or nut, but also on the threads. You don’t need to use much, but it should cover the contact surfaces.

Loctite

If any type of Loctite is used, then ARP grease should not be used, but in that case, you often do not have the same high requirements for the torque specification.

11 ▼

Reusable ARP Bolts

You can reuse ARP bolts. You can reuse them multiple times. You just need to keep an eye on how stretched they are. If you can measure this and stay within the tolerances, then reuse the bolt. If you cannot measure this, you do not know if you are within the tolerances. In that case, it is best not to reuse the bolt.

A bolt is like a spring. When it is tightened, it stretches a bit and holds things together. When it is loosened, the bolt nearly returns to its normal state. If the bolt is to be reused, it is important that it remains within the maximum tolerance for stretch.

More information on this can be found here.

12 ▼

Torque Specifications

- Grease provided in ARP kits should be used under the bolt heads

- Sometimes a mild thread lubrication is also recommended (check this for your specific application)

- Always fasten bolts in a diagonal pattern

- Always tighten in 3 or 4 steps to the recommended torque

The torque specifications in the table apply to the various thread pitches available.

▼

▼

-

Engine and tuning

- Crankcase ventilation Information

- Engine block: Parts and how they fit together

- Engine deck clearance

- Head gasket - Information

- Engine bearing installation

- Engine bearing Information

- Blow off valve: Information and assembly

- Electronic Throttle Housing - DBW Information

- Noise from engine - Troubleshooting

- ARP bolts: Material and specifications

- Assembly of connecting rods

- Automotive cooling system problem

- Engine cooling system [How does it work?]

- Engine Oil system

- Engine water pump

- Exhaust pipe: Which material should you choose? [+extra information]

- Exhaust system: Parts and assembly

- Exhaust values - Information

- Exhaust wrap

- Intercooler guide

- Oil cooler - Information and FAQ

- Piston ring installation TIPS

- What do notes on Wiseco & JE pistons mean?