Crankcase Ventilation

Crankcase ventilation, the different parts, and how crankcase ventilation works.

- Introduction

- What is crankcase ventilation?

- Which parts are included?

- Crankcase ventilation improvement

- Tuned engine -Crankcase ventilation

- Oil catch tank function?

- Different types of catch cans

- Oil catch tank installation

- Material

- Crankcase ventilation problems

- Compare oil catch cans

1 ▼

Introduction

During full throttle and high revs, the engine's crankcase pressure increases. This means that oil fog follows the crankcase ventilation into pressure pipes and intercooler with poor cooling and oil muck. An oil catch tank is connected to the crankcase ventilation to collect this oil fog before it enters the pressure pipes.

There are two types: open crankcase ventilation and closed crankcase ventilation.

- Closed crankcase ventilation leads back gas into the engine.

- Open crankcase ventilation releases this gas into the atmosphere.

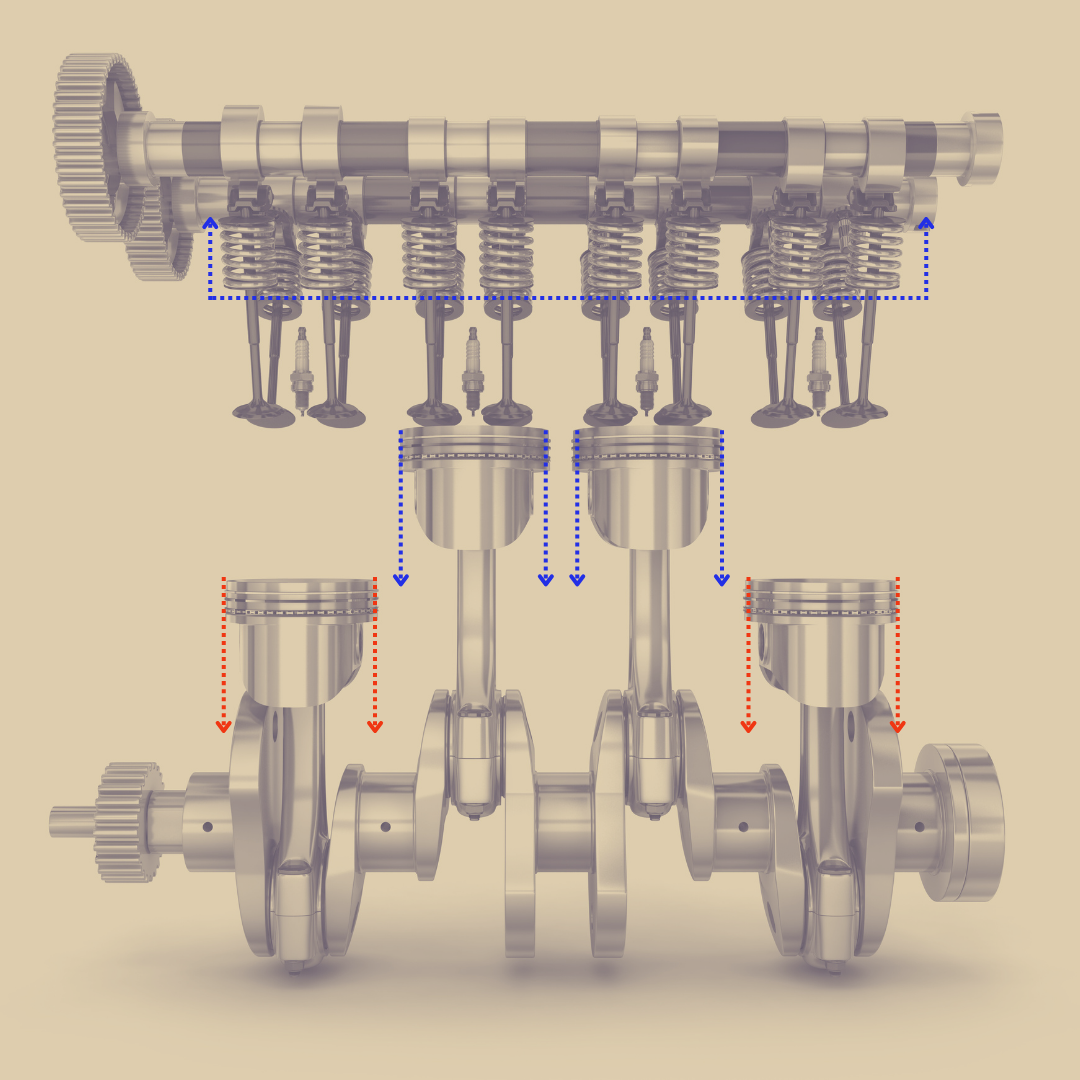

Engine crankcase pressure quickly builds up through several small sources contributing to high pressure. Keep Crankcase pressure down using crankcase ventilation through the engine block and valve cover openings. If not, engine gaskets will break, and engine power will suffer.

The most significant causes of high crankcase pressure are piston rings and valve seals that let pressure from the combustion chamber through.

Leaking turbo gaskets and broken check valves can also release pressure into the crankcase.

2 ▼

What is crankcase ventilation?

With the help of moving parts, crankcase pressure is produced and must be vented away for the engine to function correctly.

This pulsating pressure can be leveled out through internal channels in the engine. However, crank pressure is still there and must be evacuated to not get high pressure inside the engine's crankcase. This is done through holes in the engine block and valve cover. These are led into the engine's intake system through an oil catch can

Overpressure that cannot be evacuated reduces engine power and destroys engine seals.

3 ▼

Which parts are included?

One or two openings in the engine for ventilation had been enough, but then oil will leak, and dirt will enter, so more components are involved in the crankcase ventilation system.

- Engine block openings/cylinder head / both

These openings are usually found original, but when tuning the engine, they are not big enough / do not ventilate well enough. - Oil catch can

This can must have at least one inlet and one outlet

Inlet towards engine

Outlet towards the turbo intake or vented freely - Hose and connections between the engine and the oil catch can

These hoses must be able to withstand vacuum and are routed between the engine and the oil catch can - Hose and connections between the crankcase can and engine intake

This hose must withstand vacuum when it is mounted on the turbo inlet.

Often open crankcase ventilation is used in motorsport/racing by mounting a filter on this connection. The crankcase gases are then ventilated freely in the atmosphere. - PCV valve (check valve)

This is not used when the crankcase hose connects to the Turbo inlet.

4 ▼

Crankcase ventilation improvement

Improving crankcase ventilation can be done in many different ways. Still, the most common is to remove the original crankcase can and lead the gases to an external oil catch tank for crankcase gases.

Option two is to improve the flow between the cylinder head/engine block and the external oil catch tank = to get flow through which crankcase gases can ventilate. In addition, by making existing holes for crankcase ventilation bigger, ventilation is further improved.

The hoses for the crankcase ventilation should also be bigger or at least have an inner diameter as the hole they are connected to. Again, this is to not act as a restrictor.

Sometimes the main bearings sit close to the wet sump, and "chambers" are created in the engine block. In other words, it will be like several small crankcases. Here it would be best if you connected the different crankcases so pressure pulses can pass freely, which is most common. The alternative is to make crankcase ventilation for each "chamber."

It is better with crankcase ventilation that flows more from a power point of view. However, better ventilation often means more oil mist. Therefore, it is essential to have an oil catch tank that works properly.

5 ▼

Tuned engine -Crankcase ventilation

Tuned engines need to have improved crankcase ventilation because of increased consumption chamber pressure. In addition, high combustion pressure/charge pressure gives higher crank pressure as combustion gases pass past piston rings into the crankcase.

Higher RPM also builds up the crank pressure more.

6 ▼

Oil catch tank function?

An oil catch tank collects oil fog from the crankcase ventilation so it does not end up in the intake system, which impairs the intercooler efficiency and accuracy for sensors.

An oil catch can that collects oil mist is a must on tuned engines where you want to maintain engine power and clean pressure pipes.

Crankcase pressure is led through crankcase hoses through the oil catch tank, where the oil stops and the pressure continues to inlet piping. When driving, a lot of oil can be collected in the catch can, so there is an oil plug at the bottom for easy drainage.

There are also baffled catch tanks, which means that the air, with the help of channels, must take a longer path inside the container to further prevent oil fog from entering the engine intake pipes/pressure pipes. Other foam or mesh solutions can be used to filter oil mist.

7 ▼

Different types of catch cans

There are many oil catch tanks, but all are based on the principle that you have a container to collect oil mist from the crankcase. Then different kinds of solutions are added, like a built-in crankcase filter, recirculation of oil to the engine or drainage plug at the bottom, dipstick for oil level, mounting accessories, and different chambers for separation of oil mist. These are just some of the features available.

8 ▼

Oil catch tank installation

Most often, the engine's original connections on the valve cover and engine block are used to vent crankcase pressure as they are easy to use. These outlets are then led with hoses to an oil catch tank. This tank is then ventilated using a crankcase filter / small open air filter.

For best effect, a hose can instead lead crankcase gases back to the turbo intake. The crankcase gases are then helped to be sucked out of the crankcase with the help of the engine's power/flow. The disadvantage of leading the crankcase gases back into the engine is that the oil mist can also enter pressure pipes, intake systems, and sensors. This results in less engine power, and sensor values can differ because of the oil mist.

This oil mist is ventilated with a good oil catch tank/system.

Check inlets after oil several times after a new catch tank is mounted. This is to ensure clean pressure pipes, maintained cooling and sensors that work.

9 ▼

Material

Catch tanks are usually made of aluminum and are robot-welded to maintain consistently high quality. These are available in many different designs to suit most applications in terms of performance and mounting location. In addition, there are many connection options, such as barb and AN-thread.

10 ▼

Crankcase ventilation problems

Oil mist that accompanies the air from the crankcase through the ventilation hoses and forms an oil film on the inside of pressure pipes and intercooler impairs the cooling properties and causes raised inlet temperature. In addition to this, we have addressed some examples of what problems insufficient crankcase ventilation can cause:

Engine efficiency

High crankcase pressure / poor crankcase ventilation counteracts the crank/engine movement and lower engine power. This is an underestimated problem.

Oil in pressure pipes

When crankcase ventilation does not work correctly, a lot of oil fog can enter the pressure pipes/intake system, which becomes messy. This can also cause pressure pipes to loosen at boost as the parts are oiled and slippery.

Cooling

The cooler's effectiveness also deteriorates when oil ends up in pressure pipes and the intercooler. This also lower engine power.

Sensors

When oil enters pressure pipes and covers sensors, values can then show errors / wrong values. Intake temperature and MAP-sensor are two such sensors that are exposed.

Turbo

High crank pressure is one reason turbochargers push oil out of the core. In addition, high crankcase ventilation prevents turbo oil return drainage.

Turbo shaft seals

Worn seals in a turbocharger can also pass pressure from the turbo system into the crankcase through the oil drain. This is more common with larger turbochargers / turbine shaft as these components often use more clearance.

Radial seals

High crankcase pressure will damage the engine's radial seal and other sensitive gaskets/areas. This will cause oil leaks.

Clutch

High crankcase pressure pushing oil through the gearbox side's radial seal can cause clutch failure if the oil gets to the clutch friction surface.

Dirt

An open crankcase ventilation that does not have a well-functioning filter ventilates oil mist in the engine compartment, which leads to dirt and a bad smell if this oil dirt reaches hot parts such as manifolds and exhaust system.

▼

▼

-

Engine and tuning

- Crankcase ventilation Information

- Engine block: Parts and how they fit together

- Engine deck clearance

- Head gasket - Information

- Engine bearing installation

- Engine bearing Information

- Blow off valve: Information and assembly

- Electronic Throttle Housing - DBW Information

- Noise from engine - Troubleshooting

- ARP bolts: Material and specifications

- Assembly of connecting rods

- Automotive cooling system problem

- Engine cooling system [How does it work?]

- Engine Oil system

- Engine water pump

- Exhaust pipe: Which material should you choose? [+extra information]

- Exhaust system: Parts and assembly

- Exhaust values - Information

- Exhaust wrap

- Intercooler guide

- Oil cooler - Information and FAQ

- Piston ring installation TIPS

- What do notes on Wiseco & JE pistons mean?