Electronic Throttle Body - Information

E-gas, electronic throttle / throttle body, E-gas, electronic gas, and Drive by Wire (DBW) are some common names that describe a classic throttle body controlled electronically by a motor connected to the throttle body shaft.

Here we will go through more about what it entails:

- What is an Electronic Throttle Body

- Size of the Throttle Body

- Connections

- Installing the Throttle Body

- Accessories

- Advantages of E-gas

- Compare Throttle Bodies

1 ▼

What is an Electronic Throttle Body

E-gas or an electric throttle is what sits before the intake on your plenum to adjust the airflow into your engine.

An electric throttle is used together with an electric accelerator pedal. Most modern cars have electric gas (E-gas) as standard, and now most aftermarket control systems can also handle E-gas.

With E-gas, you have the ability to completely adjust the connection between the pedal and the throttle body, in other words, the driver's relationship with the engine.

The function is to more easily control, for example, cruise control, and the efficiency is generally better in modern systems. You can also avoid idle motors since the idle is controlled by programming how much the throttle body should remain open at idle.

Even limp home mode and other safety measures can be connected with the throttle body.

2 ▼

Size of the Throttle Body

Like most parts, there are various brands, sizes, and types of an E-throttle. The size of a throttle body, whether it is electric or not, plays a significant role in drivability as well as flow. A large throttle body, for example, 90mm, that only opens 4-6% allows in more air than a small throttle body that opens 10%. A large throttle body also flows more than a small one, so be sure to weigh how large is necessary.

Idle

A large throttle body that allows large amounts of air with a small throttle angle is harder to set up than a smaller throttle body. Therefore, adjustments at idle and low load require more time with a large throttle body than with a small one. It is easy to get an unstable idle if the throttle body's function is not adjusted correctly.

Flow

Determining the diameter of the throttle body required for a certain power output is difficult, but 70-60mm usually suffices to achieve high power figures.

Different Sizes

Depending on the manufacturer, there are many different sizes, but most fall within 60-90mm. Electronic throttle bodies typically range between 68-85mm.

3 ▼

Connections

A throttle body has several connections to keep track of to ensure the right accessories and function.

Inlet, outlet, mounting holes, and electrical connector.

Inlet

This is where air enters the throttle body. Electronic throttle bodies may even require an adapter to connect a pipe or a silicone hose. Keep in mind that if the throttle body is 70mm (inner diameter), a larger hose, such as 76mm (hose inner diameter), is often needed to connect to the throttle's inlet.

Outlet

The outlet of the throttle body is mounted to the intake/plenum with a welded flange. Check whether this is included or needs to be purchased separately. It is advisable to use an O-ring sealed flange as it can be reused during disassembly/service.

Mounting Holes

To attach the throttle body to the intake, there are usually bolt holes for this purpose. Some types of throttle bodies have V-band connections, but these are less common.

Electrical Connector

The throttle body's motor has a connector that connects to the ECU. This is often a 6-pin connector and controls motor functions. Check the type of connector; it is usually available where throttle bodies are sold.

4 ▼

Installing the Throttle Body

When choosing an Electronic throttle body, make sure your control system can handle it and that the functions you are looking for can be managed. You will also need an electric accelerator pedal to operate the electric throttle. When selecting size, ensure that the airflow can be managed properly by the throttle; a larger throttle body handles high airflow better but cannot be fine-tuned like a smaller throttle.

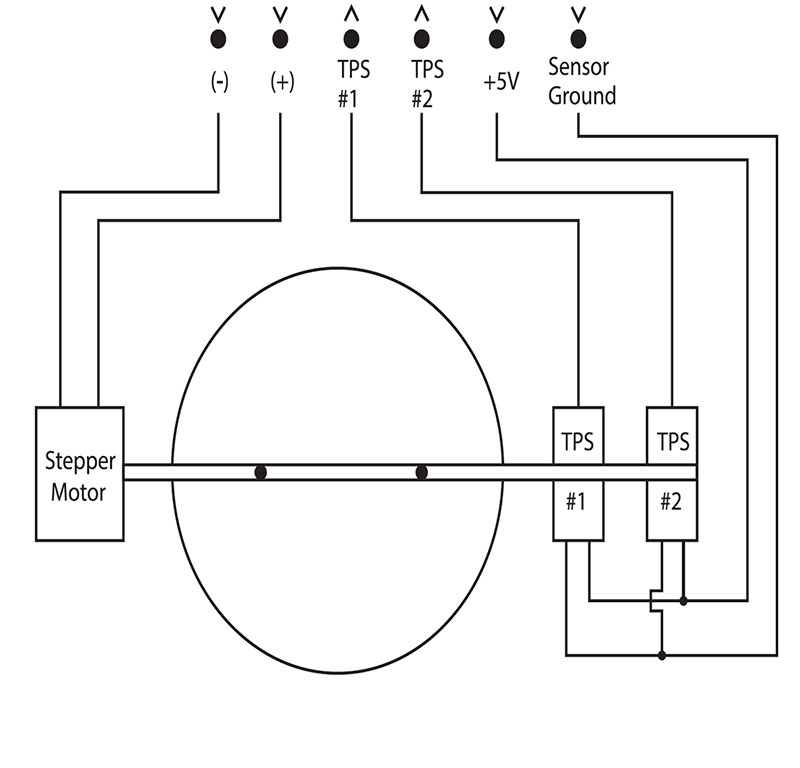

The different connections found on an electronic throttle body Note that different throttle bodies may have the functions on different pins.

- TPS 1 (Analog input x)

- Sensor GND

- Motor -

- TPS 2 (Analog input x)

- Motor +

- +5V power supply

The image of the throttle body shows an example of how the connection is made and whether the signal goes to or from the throttle body.

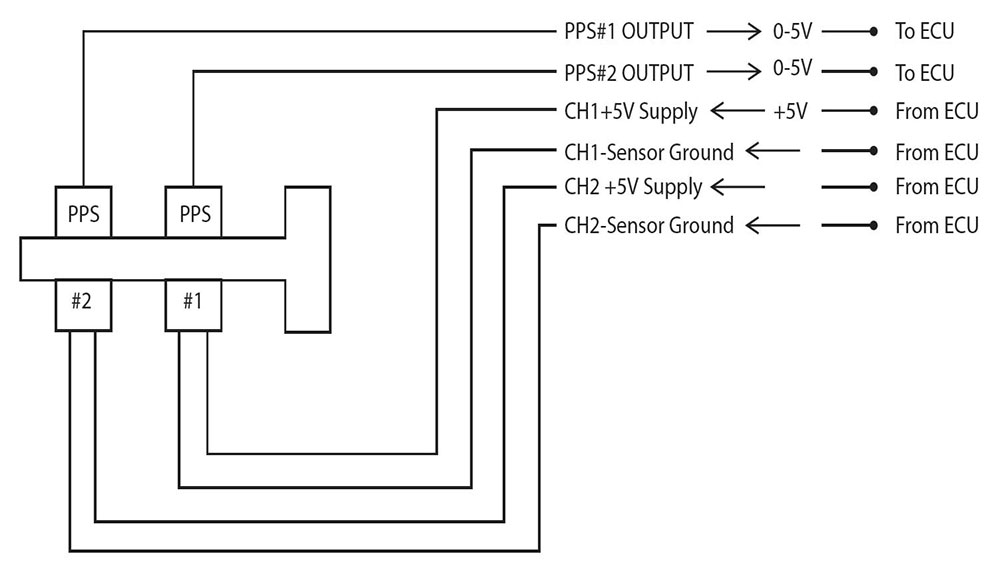

The different connections found on an electronic accelerator pedal

Note that different pedals may have the functions on different pins.

- Position sensor 1

- Position sensor 2

- ECU ground 1

- +5V from ECU 1

- ECU ground 1

- +5V from ECU 1

The image of the accelerator pedal shows an example of how the connection is made and whether the signal goes to or from the pedal / ECU.

5 ▼

Accessories

- Wiring

- Connectors: Used for correct and secure connections.

- Welded flange: For easy mounting of the throttle body.

- Adapter for the throttle body. V-band and hose connections.

- Potentiometer: A sensor that monitors the position of the throttle.

- Accelerator pedal: Controls the throttle body through the ECU.

6 ▼

Advantages of E-gas

The adjustment possibilities with an electronic throttle body are numerous. Here, only imagination sets the limit. However, a poorly calibrated electronic throttle body is not good at all. In that case, it is better to use cable control. Therefore, make sure to spend time adjusting your E-gas and take advantage of all the benefits available.

- Idle Motor

An electronic throttle body does not require an idle motor as the idle is adjusted by the throttle itself remaining open according to how it is programmed. - Dual Sensors/Sensors

The throttle and pedal have dual sensors, providing a safe function since a faulty part will only generate an error code and not a malfunctioning throttle. - Mapping

Due to the dual sensors, mapping becomes safer since a faulty/misleading TPS signal would disrupt the mapping with a classic throttle body that has only one TPS. Additionally, mapping at specific RPMs becomes easier as the throttle can be adjusted to the exact desired angle. - Control of Large Throttle Bodies

Even though a large throttle body is theoretically harder to adjust than a smaller one, it can be calibrated for easier maneuvering in the control system. - Safety

Torque limitation, check engine light, high oil temperature, etc., can trigger "limp home" mode, which is a safety mode to prevent damage to your engine. - Upshifting and Downshifting

Rev matching during upshifting and downshifting is challenging and takes time to learn. This is now possible with an electronic throttle body. The settings take time, but they will always be available when activated.

In addition to the examples above, there are many solutions on how to use an electronic throttle body to your advantage; launch control, traction control, and cruise control are just a few more options.

▼

▼

-

Engine and tuning

- Crankcase ventilation Information

- Engine block: Parts and how they fit together

- Engine deck clearance

- Head gasket - Information

- Engine bearing installation

- Engine bearing Information

- Blow off valve: Information and assembly

- Electronic Throttle Housing - DBW Information

- Noise from engine - Troubleshooting

- ARP bolts: Material and specifications

- Assembly of connecting rods

- Automotive cooling system problem

- Engine cooling system [How does it work?]

- Engine Oil system

- Engine water pump

- Exhaust pipe: Which material should you choose? [+extra information]

- Exhaust system: Parts and assembly

- Exhaust values - Information

- Exhaust wrap

- Intercooler guide

- Oil cooler - Information and FAQ

- Piston ring installation TIPS

- What do notes on Wiseco & JE pistons mean?