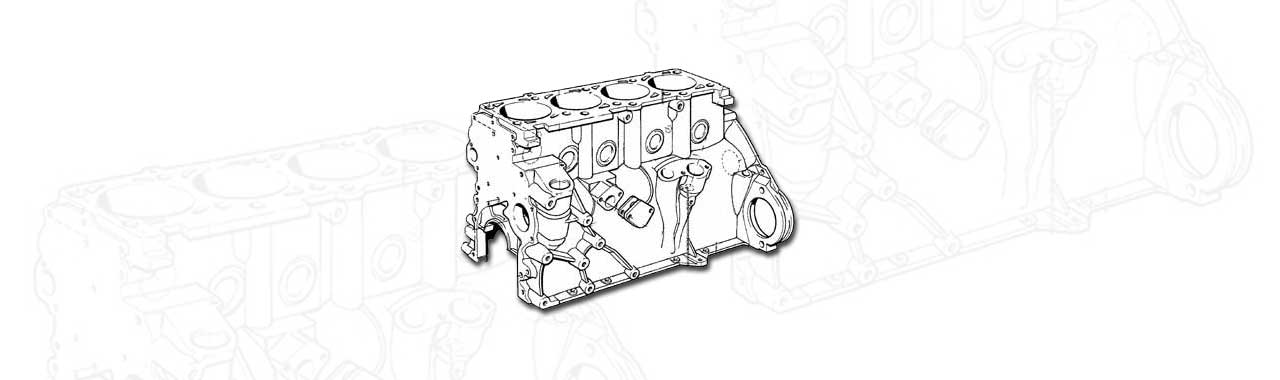

Engine block: Parts and how they fit together

Here you get a simplified overview of which parts are mounted in an engine block and how they work / are linked together.

The different parts are divided into headings as shown below. These headings together give an idea of which parts can be used and whether an upgrade is necessary or not. Please note that it may differ between different manufacturers.

The different parts of an engine block are as follows:

- Engine block

- Pistons

- Connecting rods

- Crankshaft

- Engine bearings

- Gaskets

- Bolts

- Oil pump

- Engine oil

- Conclusion

It is called short block when it is only an engine block with contents without a cylinder head. It is called a long block when a short block is fitted with a cylinder head and cam drive.

1 ▼

Engine block

The engine block is the lower part of an engine. It connects and lubricates all internal parts by the oil pump pushing oil through the engine block passages.

It is important that everything that is done with an engine is thoroughly washed and cleaned. Oil channels are the part that is easily missed as you cannot see through them like a cylinder bore, e.g. Clean these properly as you cannot visually inspect them.

You bore the cylinder bores to get a hole that is round and straight in relation to the other parts of the engine. You hene the cylinder bore so that the piston rings have a surface to wear in against for optimal seal.

Top deck the surface against the cylinder head gasket so that the engine block and cylinder head have a nice and straight surface to seal against. Other surfaces must be clean and free of scratches.

All the above parts together make an engine run without leaks.

2 ▼

Pistons

The pistons in an engine have the task of compressing the air/fuel mixture in the combustion chamber. Together with the piston rings, they seal against the cylinder walls. Select the diameter of the piston according to the bore size of the engine block. 96.25mm cylinder stroke = 96.25mm piston = The piston clearance is in the piston and is calculated by the manufacturer for optimal operation.

Compression is something that is indicated on pistons. This is for original specification unless otherwise stated. In addition to this, there are lots of other data on pistons such as dome/dish, compression height, clearance from top deck, piston bolt diameter and with this as help you can then calculate the compression ratio and more.

A piston contains, unless otherwise specified, the following parts:

- Piston

Aftermarket pistons are forged in one piece and designed to withstand high power outputs. - Pistin rings

Fitting piston rings determines how good the seal between piston and cylinder bore will be. In other words, this determines a large part of the engine's efficiency. - Piston pin

Piston bolts can be upgraded to reinforced for high power output - Clips / locking pins

This locking is a clip that is mounted at each end of the piston pin to prevent it from sliding out of position.

Aftermarket pistons can often have some kind of coating on the piston skirt. This coating reduces noise and provides better resistance to heat. Assembly of pistons is done together with the manufacturer's instructions. They are often marked and it is important that this type of marking is followed so that any offset piston pin and other asymmetric parts end up as they should.

Piston cooling nozzles are something that is good to install if there are no original ones in the engine block. It is a more advanced machining operation but helps to cool the pistons.

3 ▼

Connecting rods

Connecting rods connect pistons to the crankshaft. These are measured in length from the center small end to the center big end. Original on some models, the connecting rod can align axially in the piston. The aftermarket almost always align towards the crankshaft as there is better lubrication at this end.

The small end that sits against the piston in the piston pin has a bushing fitted. This bushing must have correct play to the piston pin and the width of the small end of the connecting rod must be correct to the piston so that nothing binds.

The big end of the connecting rods is mounted with connecting rod bolts to the crankshaft. They are divisible by so-called rod caps. There, crank bearings are mounted. It is in these bearings that oil clearance / bearing clearance is controlled by using standard or additional bearing clearance / oil film.

The different types of connecting rods available are:

- H-beam

- I-beam

- X-beam

4 ▼

Crankshaft

The crankshaft is the moving part to which both pistons and rods are connected. This is mounted in main bearings which are held together by the main caps. Thrust bearings are also mounted in at least one place / main cap. Just as described about the engine block, the crank also has oil channels that lead oil out to the main bearings to lubricate when everything rotates.

Main bearing caps, connecting rod caps and caps in general must not be twisted, turned, changed or in any way mounted differently from the way it was originally set. Then it won't work because that each cap is uniquely paired with its location.

5 ▼

Engine bearings

All parts that have a greater load on them in the engine have specific bearings mounted. For example main bearings, rod bearings and thrust bearings.

Rod bearings are mounted in the big end of the connecting rods, Main bearings are mounted for the crankshaft in the engine block and thrust bearings sit in at least one position at the main bearings to give the crankshaft axial support when the clutch is depressed (pressure plate, clutch disc, flywheel).

Original, all engines have oil pressure that provides good lubrication to all moving parts in an engine. in different situations. If something is modified / changed, the oil pressure changes and with it also the lubrication. A measured oil pressure at idle / certain RPM at one temperature / one condition does not mean that this work at other conditions. Be sure to check this if anything is modified!

When changing engine bearings, other bearing play or over-dimensions can be selected. This is common if something is modified and needs to compensate oil film / pressure.

When the desired type of engine bearing has been mounted, the bearing clearance must be checked to ensure that nothing is wrong. It is therefore not possible to rely on what is written on a box or what is believed to be the case. This must be measured with correct measuring equipment. Often simpler means such as "plastigauge" can be used.

NOTE! If larger bearing clearances on main bearings are used, it is extra important to really check that oil get properly to the connecting rods' big end. usually the oil gets too hot = thin and then escape from the main bearings and rod bearing faliure is a result.

6 ▼

Gaskets

Gaskets are for keeping tight between two components and are available in different designs. It is important to read the instructions on the product / with the manufacturer, as many may require certain techniques to

- Head gasket

This gasket has built-in rings around the combustion chambers to withstand the high combustion pressures that occur. There are also holes for water and oil between the engine block and cylinder head. This gasket is large and the bolts that tighten the cylinder head together with it must be torqued in a certain pattern in a certain order in different steps. This information is provided by the OEM or manufacturer of the bolts. - Liquid gasket

This is most often used where there are more rough surfaces, e.g. if the oil pan is made of pressed sheet metal. If gaps are too large to seal with a cardboard gasket, a liquid gasket like this is used. It is thick and is best compared to a tube of silicone.

Liquid gasket for small gaps is also available, this is usually rolled on in a thin layer. Instructions are usually found on the product. - Crankshaft seal

These seal around both sides of the crankshaft in an engine block. They seal when the crankshaft is rotating. - Other gaskets

Then there are other gaskets such as paper gaskets (cardboard gaskets), silicone gaskets, metal gaskets, etc. This can vary greatly between manufacturers and products.

7 ▼

Bolts

The engine block has different types of requirements for different parts in order for it to hold together under load. Cylinder head bolts, main bearing bolts and connecting rod bolts are something that specifically has high requirements and needs to be installed according to instructions. Reinforced bolts are often used for these areas.

The different types of bolts found in an engine block:

- Cylinder head bolts

The bolts that hold the cylinder head and engine block together. - Main studs

These bolts hold the main bearing caps together with the engine block. - Connecting rod bolts

The big end of the connecting rods is mounted with these bolts. - Other bolts

Other bolts do not necessarily have to have the same requirements as the above mentioned bolts.

With a highly tuned engine or if the car is to be used for racing, upgraded / reinforced bolts must always be used.

8 ▼

Oil pump

The oil pump works together with the engine block. Oil is pumped out through channels in the block, out to all rotating components. Even up in the cylinder head oil is led to lubricate camshafts e.g.

The oil pump is driven by the crankshaft and pumps more oil at higher revs, which is also when more oil needs to circulate in order to lubricate.

Wet sump is the most common type of lubrication system. The oil pump simply sucks oil from a bath of oil located at the bottom of the engine in the oil pan.

Dry sump oil systems has a separate container with oil that can be mounted externally from the engine, e.g. in the trunk. A different type of oil pump is now used. This draws oil from the external oil tank to supply the moving parts with oil, while pumping excess oil back to the external tank at the same time.

The oil pump has a strainer / filter that prevents dirt from entering the system. a defective oil pump causes damage to most parts of an engine. Therefore, check carefully that this is in good condition!

9 ▼

Engine oil

While mechanical components in an engine can be modified to achieve different results, the oil type can also be changed to achieve results. This is an area that is difficult. Accurate measurements in different environments and circumstances before and after the change are required. Even then, it is easy to have missed something with faliure as a result.

Use OEM specs that work and go from there.

Questions to ask yourself:

- Why do I change the oil?

- What do I want to achieve?

- Does anyone else run this oil and the same engine setup?

10 ▼

Conclusion

In addition to the above parts, each engine type and manufacturer has its own solutions and additions that are not included. This was just a simplified overview of what parts are mounted in an engine block and how they work and are linked together.

▼

▼

-

Engine and tuning

- Crankcase ventilation Information

- Engine block: Parts and how they fit together

- Engine deck clearance

- Head gasket - Information

- Engine bearing installation

- Engine bearing Information

- Blow off valve: Information and assembly

- Electronic Throttle Housing - DBW Information

- Noise from engine - Troubleshooting

- ARP bolts: Material and specifications

- Assembly of connecting rods

- Automotive cooling system problem

- Engine cooling system [How does it work?]

- Engine Oil system

- Engine water pump

- Exhaust pipe: Which material should you choose? [+extra information]

- Exhaust system: Parts and assembly

- Exhaust values - Information

- Exhaust wrap

- Intercooler guide

- Oil cooler - Information and FAQ

- Piston ring installation TIPS

- What do notes on Wiseco & JE pistons mean?