How Does a Car's Cooling System Work?

Here you get an overview of how a cooling system works and which components are included.

The different components are divided into headings listed below. Together, these headings give an idea of which parts can be used and whether an upgrade is necessary or not.

The various components of a car's cooling system.

- Radiator (radiator / heat exchanger)

- Water Pump

- Thermostat

- Expansion Tank / Boiling System

- Radiator Cap

- Heater Core (radiator / heat exchanger)

- Swirl Pot

- Cooling Fan

- Temperature Sensor (temp sender)

- Coolant Hose

- Coolant

- Compare products here

Flow Diagram for Cooling System

An overview of the components that are minimally required for a cooling system to function:

Engine -> Water Pump -> Radiator -> Thermostat -> Temperature Sensor 1 -> Engine

1 ▼

Radiator

A radiator cools the coolant, which in turn keeps the engine temperature down. The cooling is most commonly done using a water/air heat exchanger that cools the fluid in the radiator with the help of airflow or a fan.

The radiator is mounted where good airflow can be created. Whether this is at the front of the car or at the back, there should be channels that lead air through the radiator. It is also important that the incoming air can be evacuated; otherwise, the radiator will not be able to do its job as there will not be a proper airflow.

There are different types of radiators (heat exchangers). Water/air is what is used for coolant in cars.

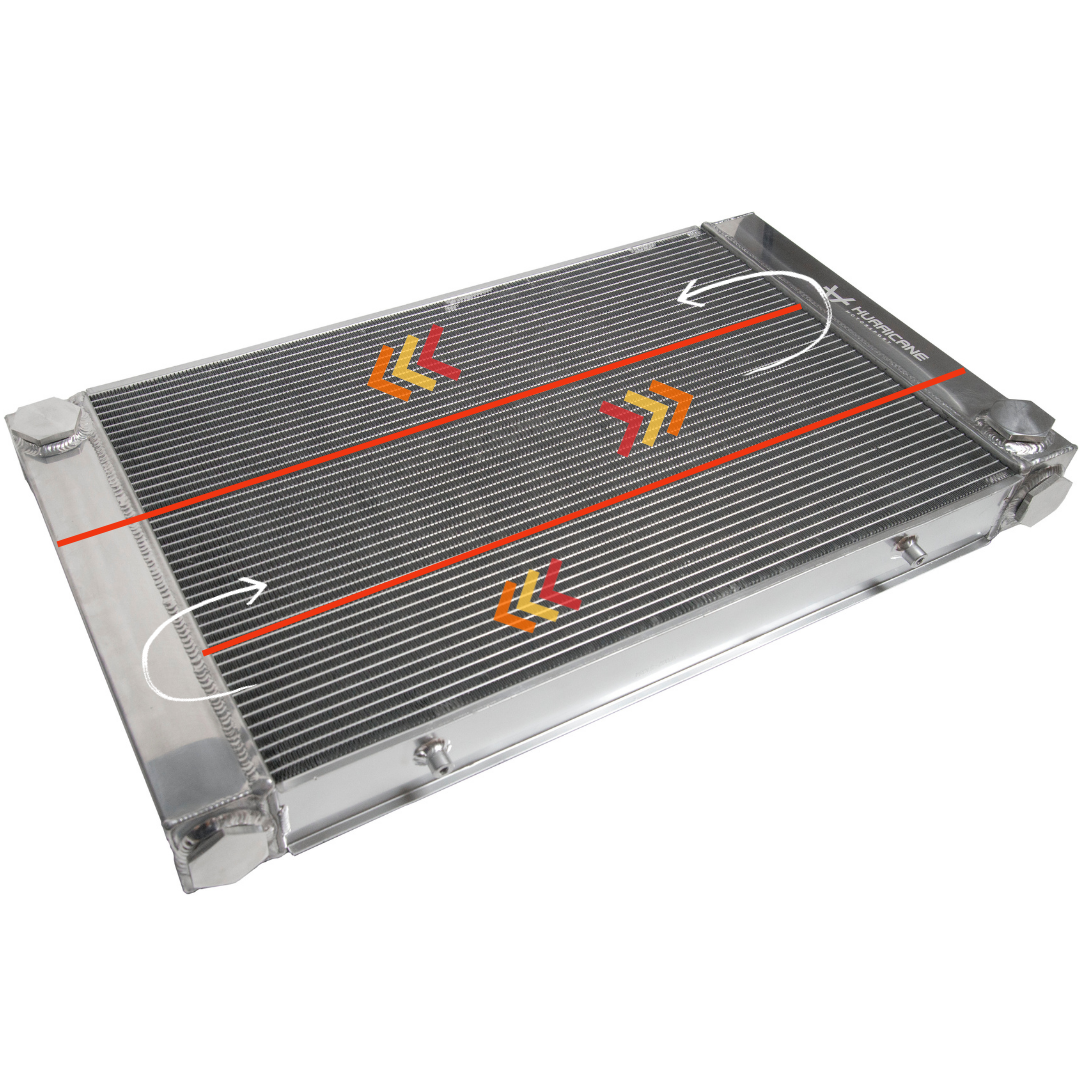

Single Pass, Dual Pass, and Triple Pass Radiators

A radiator can be built in sections. These are called single, dual, or triple pass. Simply explained, it refers to how many times the water passes through the cell pack. The idea is to achieve better cooling with more sections.

Single Pass / One Section

Here, the radiator consists of a single large section where the water passes through the cell pack once, from one side to the other.

This type of radiator has inlet and outlet on opposite sides/end caps.

Dual Pass / Two Sections

This type of radiator is divided into two sections where the water passes through the cell pack twice. The water flows from the inlet in one end cap to the other end cap and then back to the outlet in the first end cap.

This type of radiator has inlet and outlet on the same side/end cap.

Triple Pass / Three Sections

This radiator is divided into three sections, and the water passes through the cell pack three times.

This type of radiator has inlet and outlet on opposite sides/end caps.

Image example of a triple pass radiator.

Combine a large aluminum radiator made with multiple sections and airflow management through the cell pack for optimal cooling efficiency.

2 ▼

Water Pump

The Water Pump is responsible for circulating the coolant through the cooling system. The pump circulates the warm water that has been heated by the engine out through the radiator and back into the engine. This way, the coolant that has been cooled by the radiator can circulate in and cool the engine. This is how the water circulates.

An original water pump is usually mechanical and is mounted on the engine block. It is connected to the engine's crankshaft and is belt-driven. As soon as the engine turns, the water pump turns as well. When the engine revs up, the water pump also spins faster.

An electric water pump is often used in modified cooling systems where a mechanical water pump has been removed for various reasons. As the name suggests, it is powered electrically, allowing it to be controlled freely if a control system is connected to it.

You can also combine a mechanical and an electric water pump in the same system if there is a large volume of water.

3 ▼

Thermostat

The thermostat's role is to prevent coolant from being sent to the radiator unless cooling is needed. For example, when starting a cold engine, you want to reach the engine's operating temperature as quickly as possible. Only after this has occurred does the thermostat open and close to maintain the operating temperature, which is usually around 82-92 degrees Celsius.

An OEM thermostat is typically mounted on the hose leading to the radiator (the engine's outlet), in a bracket on the cylinder head or radiator.

An aftermarket thermostat is often hose-mounted, but there are also other specially built variants available.

4 ▼

Expansion Tank / Boiling System

The expansion tank/cap is positioned as the highest point of the cooling system. This allows you to add water. Air often rises to the highest point, and therefore the system can be bled through this point.

Some cooling systems do not have an expansion tank and are referred to as boiling systems. In boiling systems, the radiator cap is mounted directly on the radiator, and air is expelled from this point.

5 ▼

Radiator Cap

The radiator cap for expansion tanks and boiling systems serves the same function. They are used as a pressure relief valve in the system. The maximum pressure of the system is determined by selecting the "hardness" of the radiator cap. A cap rated for 16 psi (1.1 bar), for example, opens and releases all pressure that exceeds this.

Water boils at approximately 100 degrees Celsius. The cooling system in a car can become hotter than that. The reason the water does not boil is that the system is pressurized. A pressurized system can therefore operate above 100 degrees without boiling.

There are different types of radiator caps. Some are made of plastic and others are made of metal. Some are screwed on with threads, while others only twist a quarter turn to lock. However, they all serve the same function: to act as a pressure relief valve.

6 ▼

Heater Core

A heater core functions like a small radiator. It is heated by the coolant and is mounted in the cabin along with a fan. When the fan is turned on, it draws heat from the heater core and begins to circulate warm air in the cabin.

An aftermarket heater core operates in the same way and is often even smaller than the original.

It does not matter which direction the coolant flows through the heater core. If it is important, it is usually clearly marked on the heater core.

7 ▼

Swirl pot

A so-called swirl pot is used for systems that do not have the radiator cap as the highest point. Another reason is if it is difficult to purge air pockets from the system. In this case, a swirl pot can be installed as an additional highest point where air/gases can accumulate.

It is important that this is indeed installed as the highest point or at least as the next highest point if the radiator cap is the highest point.

Various types of swirl pots exist where a radiator cap is used, but also where only a hose connection is used that leads the air back to the radiator cap, which must also be the highest point.

The result of a swirl pot is a cooling system free of gas pockets/air trapped in the system.

A swirl pot is something that is almost exclusively used in modified cooling systems, as the problem it addresses does not exist in the original systems of street cars for normal use. In more extreme usage/modifications, problems can arise that require a swirl pot.

8 ▼

Cooling Fan

The cooling fan is used to draw air through the radiator. An example of when it starts is when the car is stationary and becomes too hot, or when the car is in motion but the airflow is insufficient. In both cases, the fan helps to circulate air through the radiator to lower the coolant temperature.

The original cooling fan can be driven electrically or powered by the engine with a so-called viscous coupling/fan coupling.

In the aftermarket for performance/tuning, almost exclusively electric fans are used.

There are both pushing and pulling (blowing) cooling fans.

- A pushing fan pushes airflow through the radiator. Airflow -> pushing fan -> cooling.

- A pulling fan draws airflow through the radiator. Airflow -> cooling -> pulling fan.

9 ▼

Temperature Sensor (Temp Sender)

A temperature sensor monitors the temperature of the coolant. When the operating temperature is exceeded, the temperature sensor signals and can, with the help of associated electronics/control systems, activate the cooling fan or other functions.

The coolant sensor can be installed both before and after the thermostat. One on the engine and one on the radiator. This way, both the hot and cold sides of the cooling system can be monitored for better control.

The temperature gauge in the car's instrument cluster also retrieves data from these sensors.

10 ▼

Coolant Hose

To connect all the components, coolant hoses are used. Common sizes to and from the radiator can be 35, 38, and 41 mm, but many other sizes are also used. For expansion tanks and swirl pots, smaller dimensions ranging from 4-20 mm can be used.

Installation of coolant hoses is usually done with hose clamps, but AN fittings and hoses are also used to connect components.

11 ▼

Coolant

The coolant circulating in the cooling system is primarily water with various additives, such as glycol. Water is simply mixed with the additive and poured into the system.

Glycol is used to:

- Lower the freezing point

- Increase resistance to corrosion

- Raise the boiling point.

Other additives that can be added to the coolant besides glycol can enhance cooling efficiency and help prevent the formation of gases/air pockets.

▼

▼

-

Engine and tuning

- Crankcase ventilation Information

- Engine block: Parts and how they fit together

- Engine deck clearance

- Head gasket - Information

- Engine bearing installation

- Engine bearing Information

- Blow off valve: Information and assembly

- Electronic Throttle Housing - DBW Information

- Noise from engine - Troubleshooting

- ARP bolts: Material and specifications

- Assembly of connecting rods

- Automotive cooling system problem

- Engine cooling system [How does it work?]

- Engine Oil system

- Engine water pump

- Exhaust pipe: Which material should you choose? [+extra information]

- Exhaust system: Parts and assembly

- Exhaust values - Information

- Exhaust wrap

- Intercooler guide

- Oil cooler - Information and FAQ

- Piston ring installation TIPS

- What do notes on Wiseco & JE pistons mean?