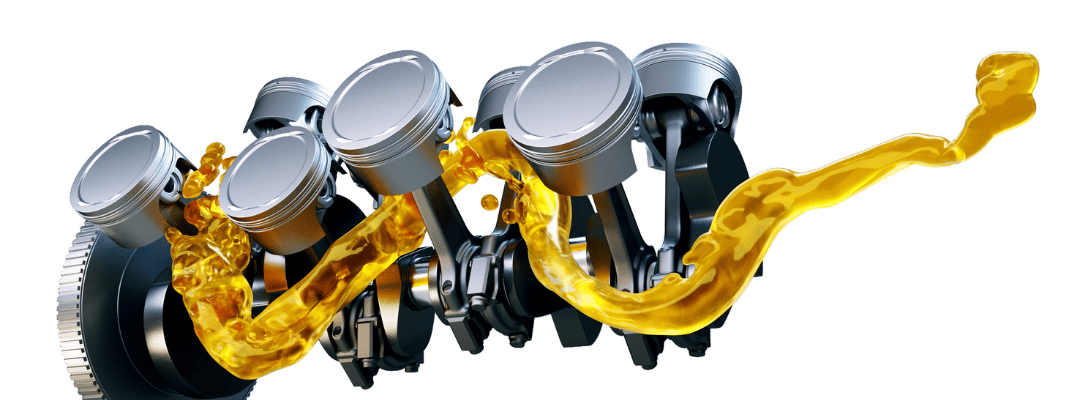

Engine oil system

An engine consists of moving parts. In order for these to be able to rotate, they are mounted in bearings that are lubricated with engine oil to reduce friction.

- Engine oil path

- Engine oil

- Oil sump

- Oil pump

- Oil filter

- Engine bearings

- Piston cooling nozzle

- Cylinder head

- Oil thermostat

- Oil catch can

- Oil cooler

- Dry sump system

1 ▼

Engine oil path

How engine oil is pumped through an engine appears similar across most engines. Presented here are the parts where the oil passes through.

- Oil sump

- Oil pump

- Oil filter

- Oil cooler

- Main bearings

- Crankshaft

- Rod bearings

- Piston cooling nozzles

- Valve lifter

- Camshafts

In addition to the above details, manufacturers have different valves, chain tensioners and actuators that also need oil. These can be placed anywhere in the order depending on the task. More important task = closer to the oil pump.

2 ▼

Engine oil

Engine oil mainly has three tasks.

- Lubricate

The engine oil's purpose is to create a lubricating film on the moving parts of the engine to minimize wear. - Cool

Without engine oil flow, temperatures would have risen far outside the oil temperature range. - Clean

Despite accuracy when assembling an engine, particles constantly enter that should not be in an engine, regardless of whether they are from the engine or due to external factors.

The combustion is one such thing that contaminates the oil. Both soot and fuel can pass into the oil and must be cleaned. The oil transports this to the oil filter. This shows how important an oil change is!

If you are unsure about which type of oil to use, it is recommended that you use the recommended one from the engine manufacturer. If you have made extreme modifications to the engine and will use the car for motorsport/racing, it may need to be replaced with a more suitable type.

Two major factors that affect engine oil performance are viscosity and temperature.

Viscosity

The thickness of the oil is indicated in viscosity and is measured by flow resistance / how slowly an oil flows. We are talking about two numbers here. An example is 5w and 30 (5W30). The first indicates how the oil flows when cold / on startup. The second number tells how the oil flows within operating temperature.

Low viscosity = Lower number = The oil flows more easily = "The oil is thinner" = Protects engine parts better at low temperature = More common in cold climates.

High viscosity = Higher number = Oil flows more slowly = "Oil is thicker" = Protects engine parts better at high temperature = Maintains film strength at high temperature = More common in racing.

Temperature

The oil has a temperature range in which it works best. When the oil is outside this range, it does not lubricate as well and several times more wear occurs. Therefore, it is important to have the correct engine oil for the right operating conditions. Therefore, it is important to warm up the oil before putting more stress on the engine.

In racing, it is even more important to warm up as the margins are often small before problems start to arise.

3 ▼

Oil pan

In both wet sump and dry sump oil pans, oil is collected where the oil pump can reach.

Wet sump is exactly what it sounds like. The oil collects at the bottom of the engine and is therefore called wet sump.

Dry sump also collects the oil at the bottom of the engine, but this oil is then passed on to a specific oil container called a dry sump tank. From here, the oil is then pushed out into the system again.

Splash guard / Baffled oil pan.

When a wet sump is used, oil sloshes around in the bottom of the engine and can be caught by the crankshaft, which lowers engine power, the efficiency of the crankcase ventilation cleaning system and deteriorates the properties of the oil. Therefore, some form of splash guard is often used to prevent engine oil from being caught by the crankshaft.

Oil plug

The oil pan has an oil plug to be able to change the oil. The oil plug is mounted as the lowest point, so when this is unscrewed, the oil flows out with the help of gravity.

The oil plug may have an outlet for oil temperature. This is a simple way to measure the temperature of the oil in the oil sump.

Dry sump

An oil pan for dry sump systems has several different outlets and the oil pump is often mounted directly against these. These are divided into steps

Suction step.

Here, oil is sucked from the sump and leads this to the dry sump tank. This is to always have a full oil tank, which means that you always have full oil pressure.

Pressure step

From the bottom of the oil tank (dry sump tank), the oil pump pushes out oil to the engine through the hole where the original oil pump once sat.

Crankcase ventilation

In a dry sump system, the suction stage also functions as crankcase ventilation. It is a great advantage to use a dry sump system as excess pressure in the crankcase becomes non-existent.

Turbo oil drain

Regardless of whether the turbo is fitted originally or is retrofitted, excess oil from the turbo is led back to the oil sump, this applies to both wet sump and dry sump, although dry sump systems have alternative solutions for turbo applications.

Different oil pans materials

Oil pans for wet sumps are mostly made of sheet metal or cast aluminium

Oil pans for dry sump systems are almost always milled out of a piece of aluminium.

4 ▼

Oil pump

The job of the oil pump is to push out engine oil to all the bearings in which the moving parts lie and rotate. Rule number 1 in an oil system. Keep an eye on the original oil pressure and take measures if this becomes lower or higher at certain rpm = Oil pressure log.

Oil pressure log

When you got desired engine function and oil pressure

Measure engine oil pressure at Idle, mid rpm range and high rpm range.

Example.

Idle - x bar

Mid rpm range - x bar

High rpm range - x bar

Set up ECU pressure warnings and check the pressure manually once and a while. It should not change from your logged values.

Pressure

The oil pump is responsible for circulating oil throughout the engine, creating a protective oil film that prevents engine components from rubbing against each other. As the engine load increases, the oil pump needs to maintain higher pressure levels. To achieve this, the oil pump typically spins faster at higher engine speeds, which results in increased pressure.

It is crucial to know the oil pressure requirements of an engine to avoid potential damage to rotating components.

- Engine oil

When engine oil becomes too hot and overworked, it thins out and is more volatile, resulting in quicker evacuation from engine bearings and a drop in oil pressure. - Engine bearings

To increase the safety margin of a high-performance engine with high combustion pressures, larger bearing clearances can be chosen for engine bearings. This enables the creation of a thicker oil film, providing a better safety margin. However, this places significant demands on the oil pump, as well as the choice of oil and oil temperature.

Flow

When an engine operates at high speeds or under high load, it generates more heat. To ensure better cooling, a higher oil flow is required to replace the engine bearing oil film at a faster rate.

If you switch to engine bearings with more clearance, you may need to install an oil pump with a higher flow. Larger engines with more cylinders and moving components require a higher flow oil pump than smaller engines because they have more bearings that release oil and, therefore, require higher oil pressure.

High flow oil pump

For tuned engines, a high flow oil pump can be used for the same reasons as mentioned above:

Oil pressure

Higher flow should mean a maintained oil pressure at higher rpm compared to the original oil pump.

Cooling

Better cooling at higher loads on a tuned engine with more flow.

Engine bearing clearance

Greater bearing clearance requires more flow to maintain oil pressure. Even high viscosity oil can work well with larger bearing clearances.

RPM

Higher rpm places higher demands on the oil film, and a high-flow oil pump helps create good conditions for this.

Cooling

It's important to note that the temperature measured in the oil pan can be significantly lower than the actual temperature of the oil in a bearing race. Therefore, it's crucial to have a safety margin that accounts for the oil's maximum temperature. Keep in mind that the low temperature measured in the oil pan may actually be too high for the bearing raceways.

Reinforced oil pump

An improved oil pump should be distinct from a high-flow oil pump. An improved pump is often a mechanically upgraded pump that fixes any problems the original pump has or gets with a tuned engine.

Big engine

Large engines with many cylinders / moving parts place higher demands on the oil system as there are more bearings where oil is evacuated back to the oil sump. Engines with more moving parts have higher flow oil pumps than smaller engines.

Problems

These can be many but are remedied by the points above and below

- Bad seal between oil pump and engine block

The o-ring/gasket between pump and engine is not tight and the pump cannot work fully. - Dirty oil

Dirt damages the oil pump, which has small clearances. This leads to poorer flow and many consequential problems

5 ▼

Oil filter

Motor oil circulating in an engine collects dirt in one way or another. To prevent this from reaching engine bearings, valves, oil pump and other critical parts that can cause engine failure, an oil filter is used.

Different types

Oil filters are available as steel filters (spin-on) and insert filters (cartridge). Steel filters sit externally on the engine and often have a built-in overpressure valve. An insert filter is inserted into a filter housing that is mounted on the engine body.

The filter element

There are different levels of filtering depending on the application. Everything from 40 microns down to 10 microns.

Larger number indicates the size of the holes and means that the filter lets larger particles through.

Smaller number = better filtering. Note that better filtration can also mean higher back pressure unless the filter area is larger.

Material

Paper materials have previously been the most common, but this has shifted almost exclusively to synthetic materials and in the aftermarket also stainless steel filters, which are more exclusive and then also cost more.

Standard engine oil filters is also used on tuned engines as it often can handle enough flow and temperature. But be sure to know if your filter works for your application before your engine gets problems. This type of problem can cost an engine failure.

Pressure relief valve

In most spin-on steel filters and oil filter housings, there is a pressure relief valve if the oil filter becomes full or get pressure peaks. This allow the oil flow to continue, but the filtration is then completely absent instead, which in turn can cause engine damage. Therefore, make sure you know the maximum pressure and adapt the oil filter to the application. For example, if you have changed to a high-flow oil pump, the capacity of the oil filter must also be checked and adjusted accordingly.

6 ▼

Engine bearings

Main bearings

The main bearings are the first bearings after the oil filter and oil cooler. This is to ensure proper oil pressure. Larger engines place higher demands on oil pressure and flow due to more bearings.

Rod bearings

In the crankshaft before the rod bearings, oil pressure is converted into rotational energy as a crankshaft is designed to "throw" oil to the rod bearings to ensure that oil reaches out properly.

Despite this, crank bearings are a critical part, especially in a large engine with many main bearings before the oil reaches the rod bearings. Some of these are:

- Temperature

Before the engine oil reaches the rod bearings, it has time to be further heated by the main bearings. This can quickly negatively affect the strength of the oil film - Oil pressure

Because oil becomes more volatile at higher temperatures and main bearings heat up the oil quickly, the oil pressure can drop locally in the area around the main and rod bearings. Therefore, the rotational energy of the crankshaft is important here. - Lubrication

Since both temperature and oil pressure have had time to deteriorate before the oil reaches the rod bearings, we see how important it is to have correct bearing clearance, pressure, temperature and all the things we go through to avoid a rod bearing failure, which a common bearing failure point!

Axial bearings

Thrust bearings usually only have oil mist as lubrication. Therefore, high demands are placed on a strong oil film, as thrust bearings can be worn hard with a strong clutch. When the clutch is pressed in, the crankshaft is moved axially and rests against the thrust bearings. When the engine is also cold and the engine oil has not reached operating temperature, the greatest wear occurs.

Cam bearings

Camshaft bearings are only fitted to certain engines. Often, camshafts operate without bearings with only paths milled to resemble bearings where the oil can form a film between the camshaft and the engine to avoid wear.

Piston rings

Piston rings have lubrication through oil film from cylinder walls. Cylinder walls are honed to maintain oil film which minimizes cylinder bore wear.

Again, rich fuel mixture = low lambda on tuned engines is a cause that washes away this oil film and increase wear. But the fuel is needed as a safety margin for cooling in the combustion chamber instead.

7 ▼

Piston cooling nozzle

A piston cooling nozzle is mounted inside the engine block and is connected directly to the main oil passage. The purpose of the nozzle is to cool the piston by spraying oil on the underside.

Due to the extra cooling, the piston does not have to hold as much heat and can then be manufactured with less material, which makes it lighter. Most often, only piston cooling nozzles are used for extra safety. Pistons are manufactured with good safety margins to achieve high reliability.

Some engines that do not have these nozzles fitted originally can have them retrofitted by drilling holes and threading in the engine block below the pistons. This is an advanced intervention that is left to the engine company. But the idea is that holes are drilled in the engine block's oil passage and nozzles are fitted and directed to spray oil under the piston. With retrofitted oil cooling nozzles, the engine's oil pressure can drop as more stops with more "leakage" occur.

8 ▼

Cylinder head

After oil has passed the the engine bottom end, which is most critical when it comes to oil lubrication and pressure, oil is transported to the moving parts of the cylinder head. These do not have as high a load and can therefore be prioritized after the bottom end of the engine.

With tuned engines/racing and high valve pressures, but also variable camshafts, correct oil pressure and lubrication are needed to keep valves, seals and camshafts in good shape.

Excess oil usually flows back to the oil sump using the law of gravity. Therefore, some cylinder heads may need extra drainage as a lot of oil can "get stuck" up in the cylinder head.

Oil pressure

A proper oil flow to the cylinder head is important as tuned engines with strong valve springs produce high pressures on the installation surface against camshafts. This causes an incredible amount of wear without correct oil flow and pressure.

Even variable camshafts require proper oil pressure, as cam times suffer directly in case of deviating oil pressure, which results in lower engine power.

9 ▼

Oil thermostat

In order for engine oil to function optimally, there is an optimal temperature for each type of oil and area of use.

Without a thermostat that controls the oil temperature, there are three scenarios:

- Too cold oil

During calm driving or in cold climates, the oil temperature may become too low or take a very long time to get up to operating temperature. - Too warm oil

Active driving or in hot climates, the oil temperature may rise above the recommended temperature. - Optimal oil temperature

This is the condition when the oil is neither too hot nor too cold. Exactly as it should be for the best performance.

With an oil thermostat fitted, the oil temperature is actively adjusted to the optimum temperature.

When the oil gets too hot, the thermostat opens and releases oil through the oil cooler, which lowers the oil temperature. When the desired temperature is reached, the thermostat closes again. In this way, the thermostat works actively and maintains optimal oil temperature.

There are different types of oil thermostats.

An originally fitted one which is usually located in the oil filter housing. This type often has a higher opening temperature than aftermarket oil thermostats, this suits standard vehicles well. In racing, cooling is often a problem and a thermostat with a slightly lower opening temperature is used to regulate the oil temperature before critical values are reached.

10 ▼

Oil catch can

An oil catch can is assembled together with the crankcase ventilation and has the function of capturing the oil mist that gets out of the crankcase ventilation. The oil catch tank prevents this oil from getting to the pressure pipes / intake system, which affects sensors/transducers negatively.

An oil catch tank is used in wet sump systems and is mounted between the intake (vacuum) and engine (pressure).

The intake must have a vacuum / negative pressure, which helps to suck / lead out the excess pressure inside the engine. Without an oil catch tank, oil mist would have followed into the intake and smeared the sensors with oil. But with the help of an oil catch tank that has a built-in filter and a labyrinth-shaped passage in it, oil mist is prevented from contaminating sensors and inlet pipes.

You will not be completely free from oil mist, but a well-constructed crankcase ventilation almost eliminates this kind of problems.

11 ▼

Oil cooler

To keep the temperature of the engine oil down, an oil cooler is required.

When the engine works at high speeds or with retarded ignition, it generates high heat. This heat is led away with the help of water and oil, which should keep the engine temperature down.

Engine temperature

The oil has a major impact on engine temperature and is kept down with the help of an oil cooler.

Just like a water cooler, air must be directed through the cooler's cooling fins. By directing air through the cooler, you greatly increase the cooler's cooling capacity. Therefore, be careful about this when installing, as you both gain engine power and a margin of safety from this.

Oil thermostat

In order for the oil temperature not to take too long to reach the optimum temperature, you want to prevent the engine oil from passing through the oil cooler before it has reached its working temperature. Therefore, an oil thermostat is used which only releases oil through the oil cooler when the oil temperature has reached operating temperature.

12 ▼

Dry sump system

The different parts of a dry sump system

- Oil pan (Dry sump oil pan)

- Oil pump (Dry sump oil pump)

- External oil container (Dry sump tank)

- Oil filter

- Oil filter mount

- Oil cooler

- Oil pump adapter (To the OEM pump placement)

- Fittings and hose

- Drive belt (To the dry sump pump)

- Crankshaft pulley (To the dry sump pump)

- Ventilation

▼

▼

-

Engine and tuning

- Crankcase ventilation Information

- Engine block: Parts and how they fit together

- Engine deck clearance

- Head gasket - Information

- Engine bearing installation

- Engine bearing Information

- Blow off valve: Information and assembly

- Electronic Throttle Housing - DBW Information

- Noise from engine - Troubleshooting

- ARP bolts: Material and specifications

- Assembly of connecting rods

- Automotive cooling system problem

- Engine cooling system [How does it work?]

- Engine Oil system

- Engine water pump

- Exhaust pipe: Which material should you choose? [+extra information]

- Exhaust system: Parts and assembly

- Exhaust values - Information

- Exhaust wrap

- Intercooler guide

- Oil cooler - Information and FAQ

- Piston ring installation TIPS

- What do notes on Wiseco & JE pistons mean?