Problems with Distributors (And Solutions)

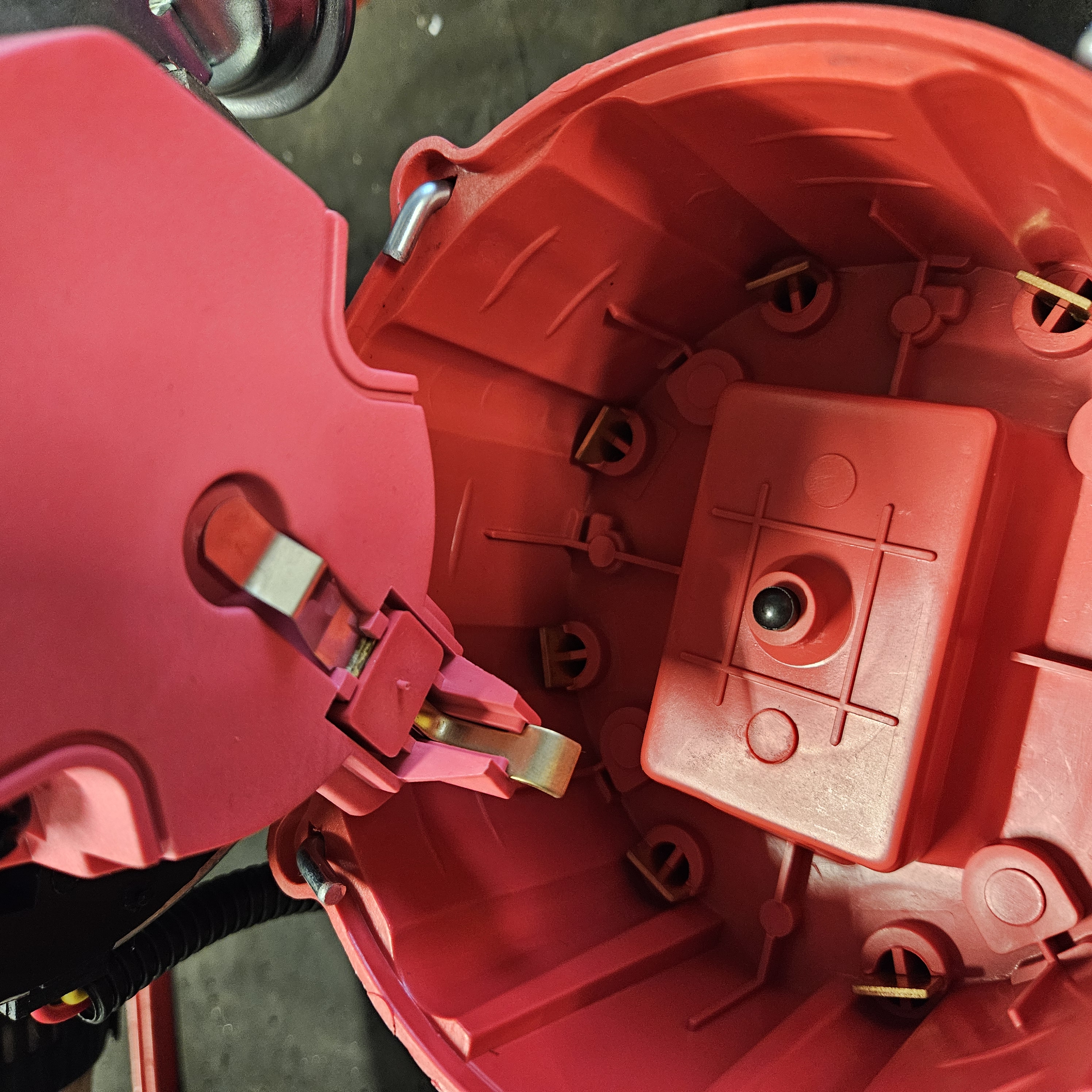

Fastening

As always when assembling products. Make sure that the screws and fasteners are properly installed. You should never assume that someone else has done this for you.

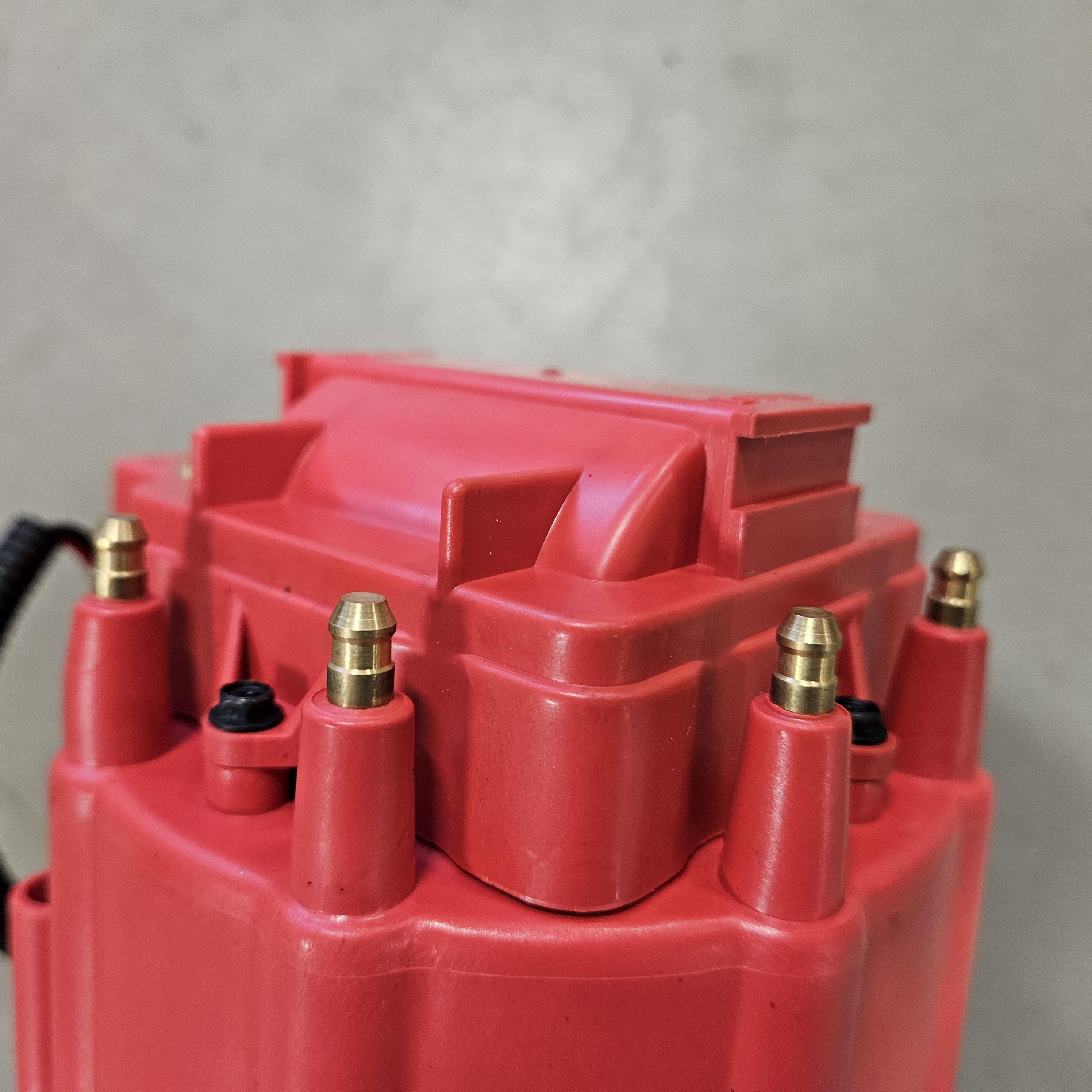

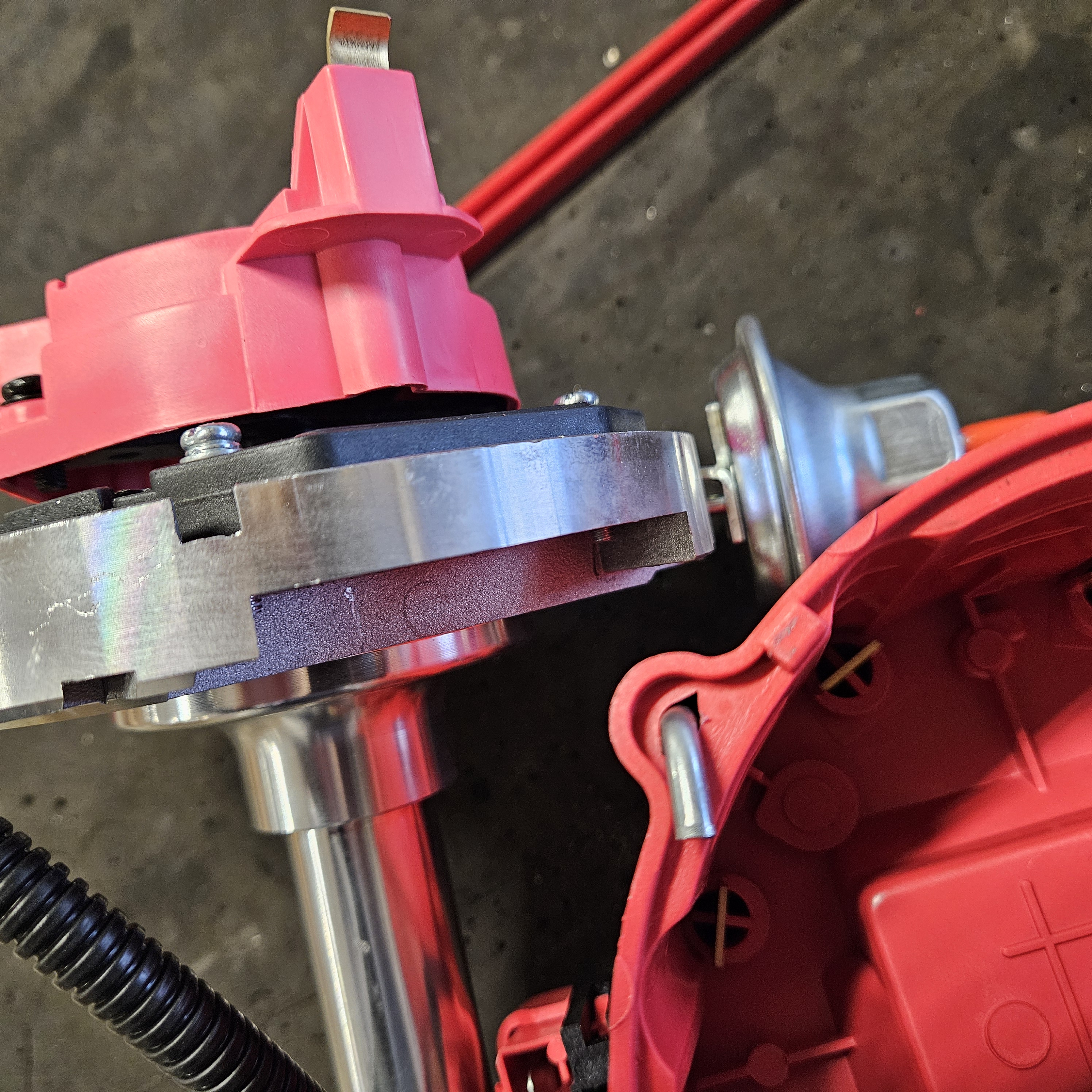

Built-in Ignition Coil

A rotor in an HEI distributor (Ready-To-Run Distributor) is larger than the corresponding distributor with a separate ignition coil.

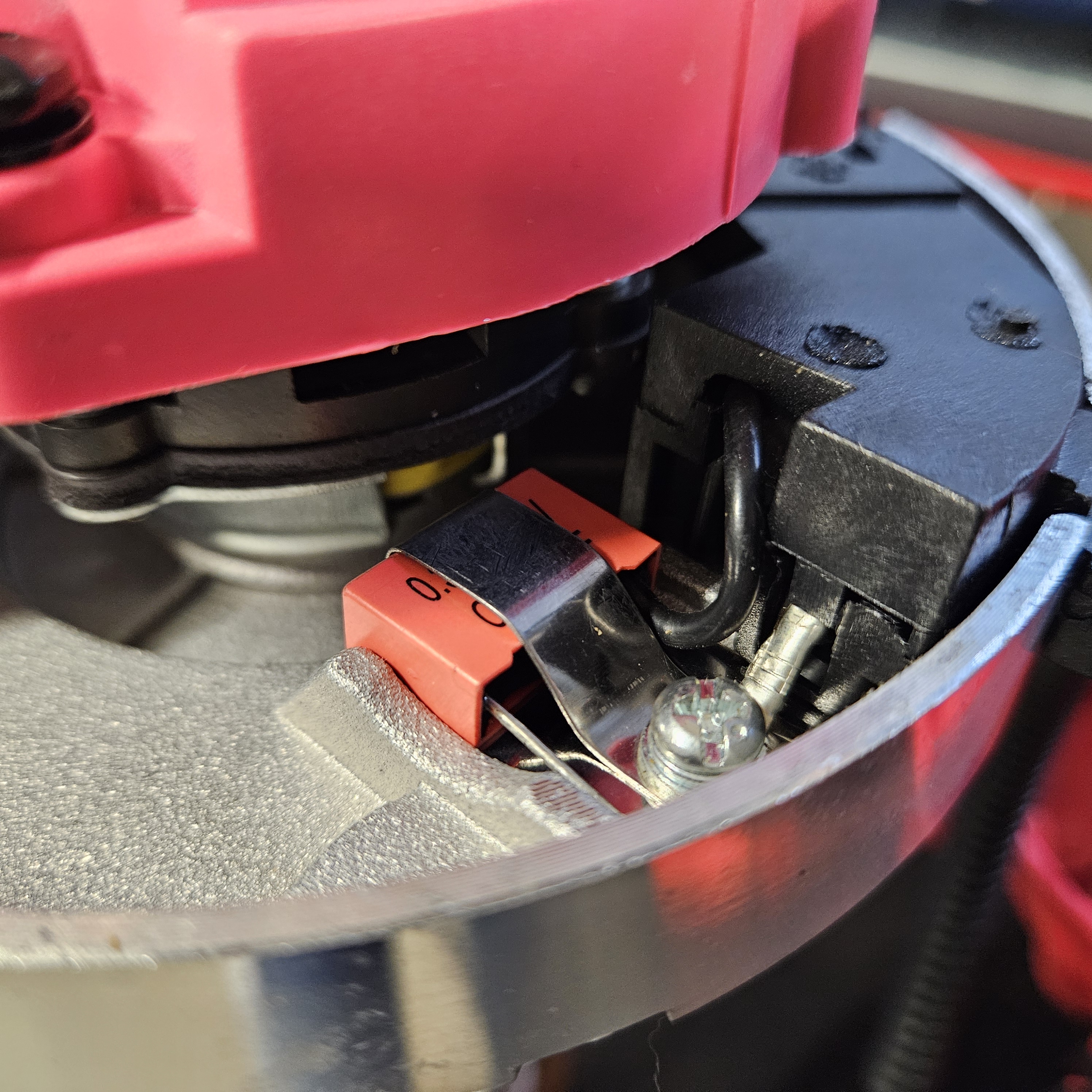

Electronics

If your distributor has electronics, make sure they are properly mounted and not interfering with anything. Any pins and cables should not be damaged and should be well protected from moving parts.

Ignition Cables

When installing ignition cables, they must be undamaged and have good contact with the distributor. An ignition cable with poor contact will quickly degrade in performance and there is a risk of damaging the contact surface.

Ignition Coil

If your HEI distributor is not working, part of the troubleshooting is to check the ignition coil.

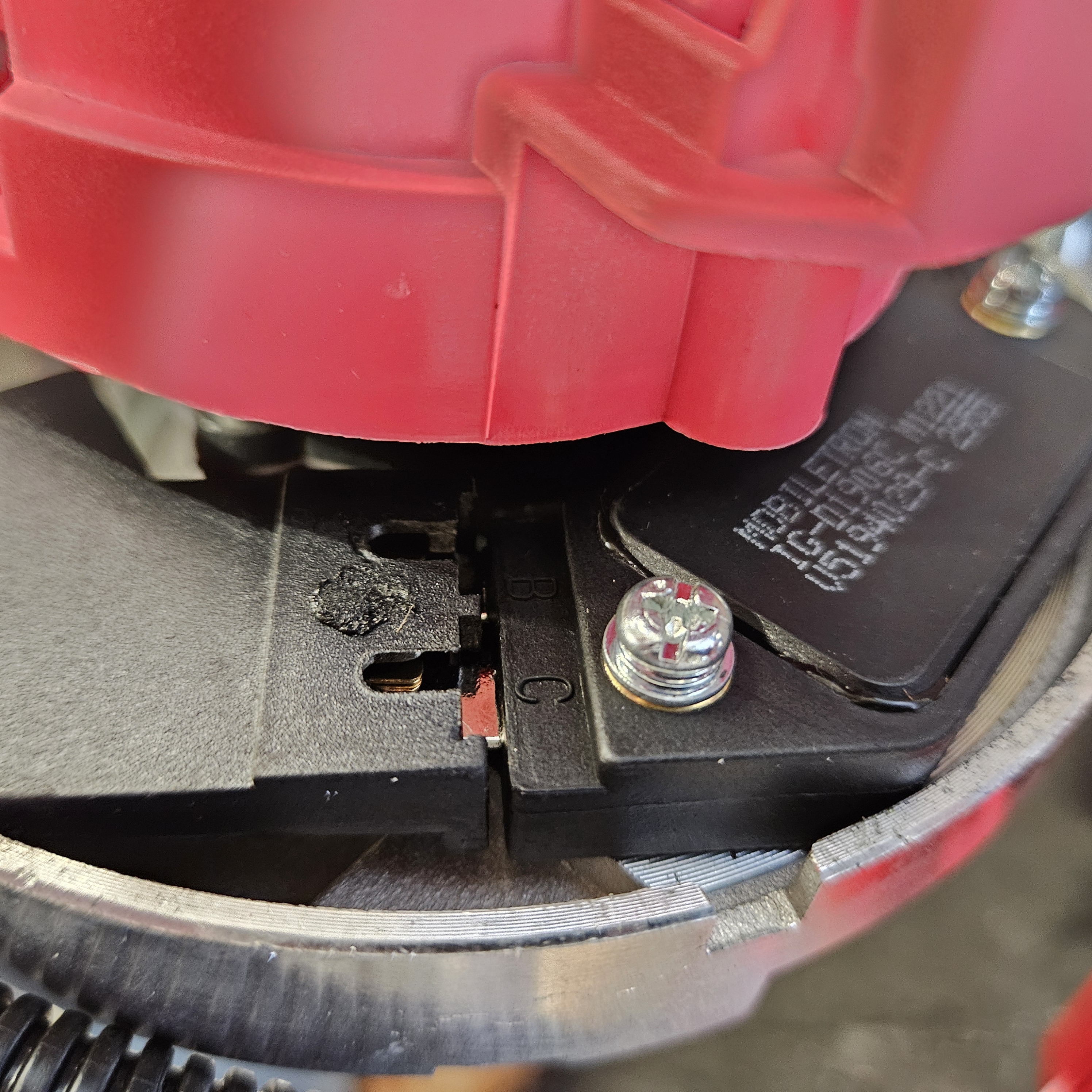

Assembly

When assembling the distributor, rotor, distributor cap, and everything related to it, be sure to follow the alignments and markings carefully. If things are installed incorrectly, the engine will not start. Even worse is when you experience strange symptoms because parts are installed slightly wrong / offset.

Variable Timing

If your distributor has variable timing, for example, through a vacuum advance, make sure that it is not misadjusted. This can significantly affect starting and engine performance.

Vacuum leaks and damaged hoses are common issues.

Contact Surfaces

A recurring cause of ignition problems is worn and corroded contact surfaces. Make sure that your contact surfaces are in good condition, otherwise you may experience strange issues.

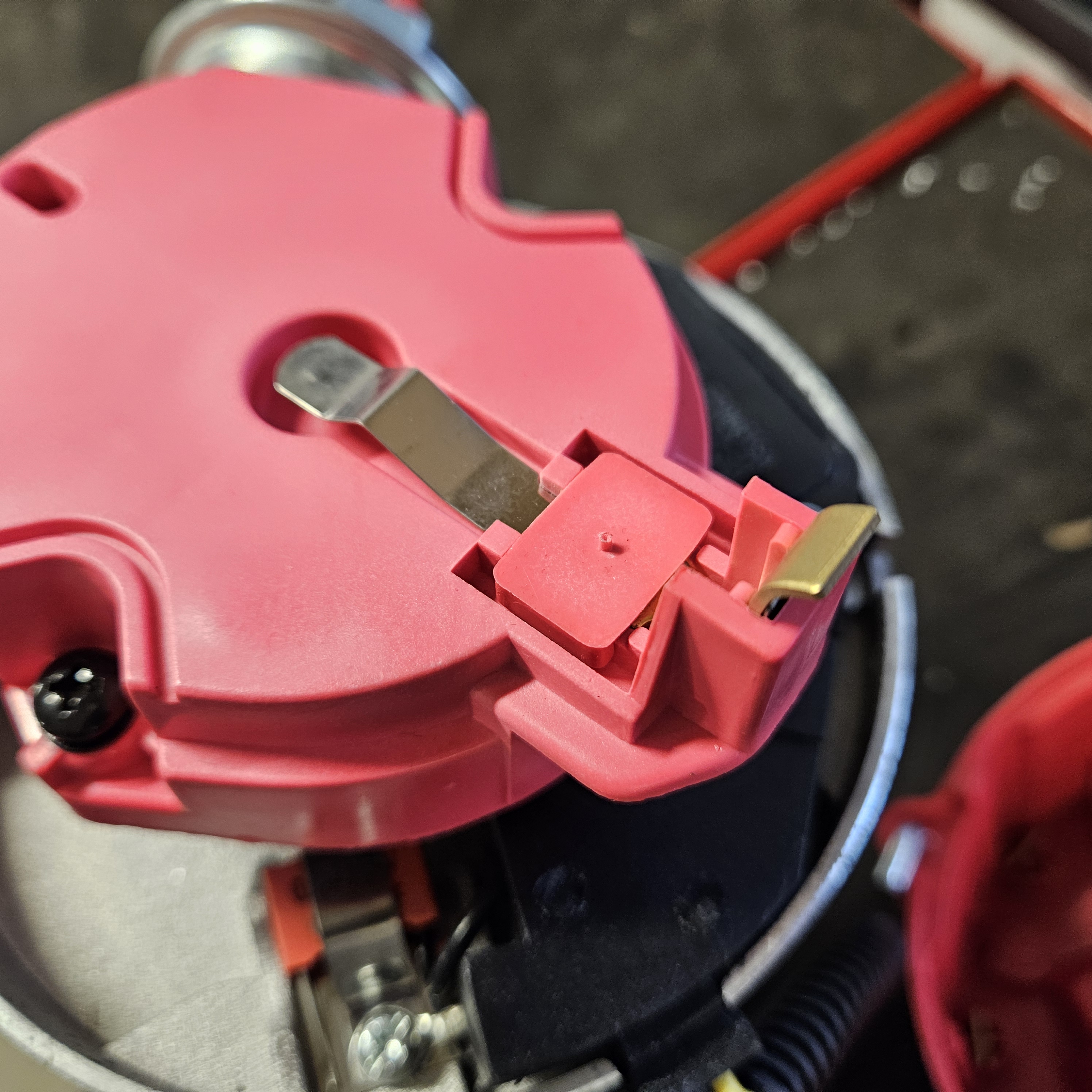

Rotor to Distributor

If your rotor does not have proper contact with the distributor cap, you will experience strange ignition problems. Alternatively, there may be no spark at all.

If you replace the distributor cap, make sure to get an EXACTLY identical one in terms of distance/size, as many have had issues with poor contact, causing the engine not to start or resulting in weak spark, which can be harder to troubleshoot.

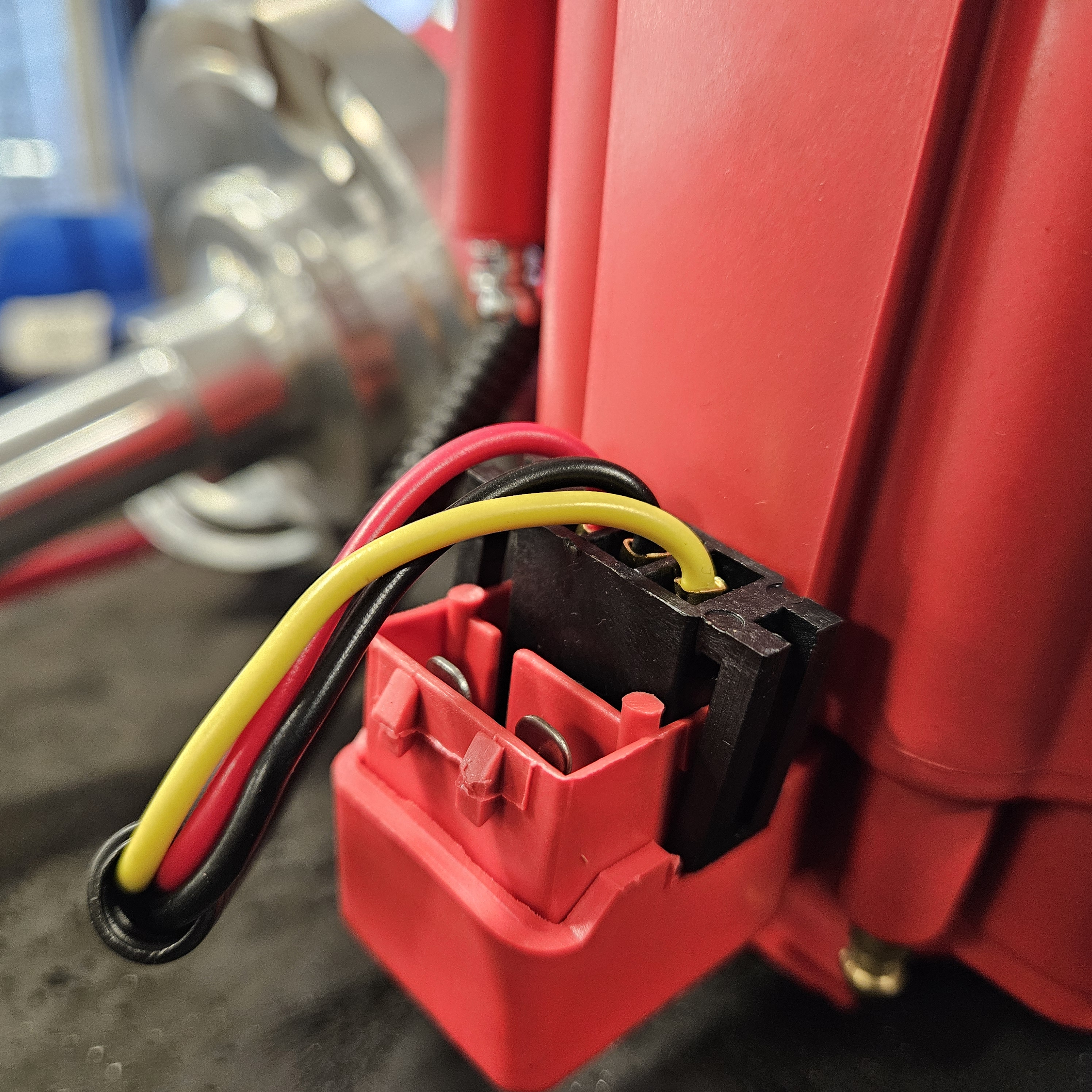

Correct Connection in the Right Place

Make sure that all connectors and connections go to the correct place. It's easy to mistakenly install a connector in the wrong spot.

When installing a so-called HEI (High Energy Ignition) / Ready-To-Run distributor, it is important to have +12v power and ground on the red and black cables, as older cars often use ballast/resistor and do not provide enough voltage.

You can measure 12v, which then drops when you install a load.

Cables / Connectors

Are the cables and connectors properly secured?

Pull on them a little and make sure you don't leave anything to chance. It could be as simple as a poorly installed cable lug.

▼

▼

-

Engine management / Electric

- Engine control system: The various parts available

- Ignition System Information

- Install motor control

- Pressure sensor - Information

- Temperature sensor - Information

- Buttons - Switches - Information

- Connectors - Information

- Cooling fan car - Information

- Exhaust gas temperature sensor - EGT Sensor

- Lambda sensor - Wide band lambda

- Relay - Information

- Relay box - Fuse central

- CAN protocol - Canbus

- Ethanol sensor - Information

- Gauges and Dash

- Trigger sensor information

- Dimensioning of cable [and fuse size]

- Distributor Problems (And Solution)

- How does an Ignition Coil work?