Fuel pressure regulator

How a regulator works and how to adjust it. (does NOT include carburetor)

- How does a FPR work?

- Connections

- Fuel pressure regulator adjustment

- Quality

- Pressure drops when engine is turned off

- Fuel in vacuum hoses

- Connecting the fuel pressure regulator

- Compare fuel pressure regulator here

1 ▼

How does a FPR work?

Injectors have around 3 bar (43.5PSI) of fuel pressure at idle. A fuel pump cannot deliver this pressure with an open return line back to the fuel tank. That is why a fuel pressure regulator is mounted after the fuel rial where the injectors are located. Now we can build up pressure between the fuel pump and the fuel pressure regulator.

If you use a fuel pressure regulator set to 3 bar, you will get a fuel pressure of 3 bar. If you use a fuel pressure regulator set to 4 bar, you will get a fuel pressure of 4 bar. -Easy!

But at high revs you want more fuel in the engine. Not only the stoichiometric ratio (Lambda 1) but more fuel for cooling the cylinders. This can be achieved by extending the injector opening times, but for this you have to use larger injectors than necessary. Therefore, we use engine pressure to increase fuel pressure with engine speed and boost.

If you use a fuel pressure regulator that is set to 3 bar and your engine delivers 1 bar overpressure then you get 4 bar fuel pressure. (3 bar spring pressure + 1 bar boost pressure from the engine). This is called a linear (1:1) fuel pressure regulator and is most commonly used in both OEM and aftermarket applications.

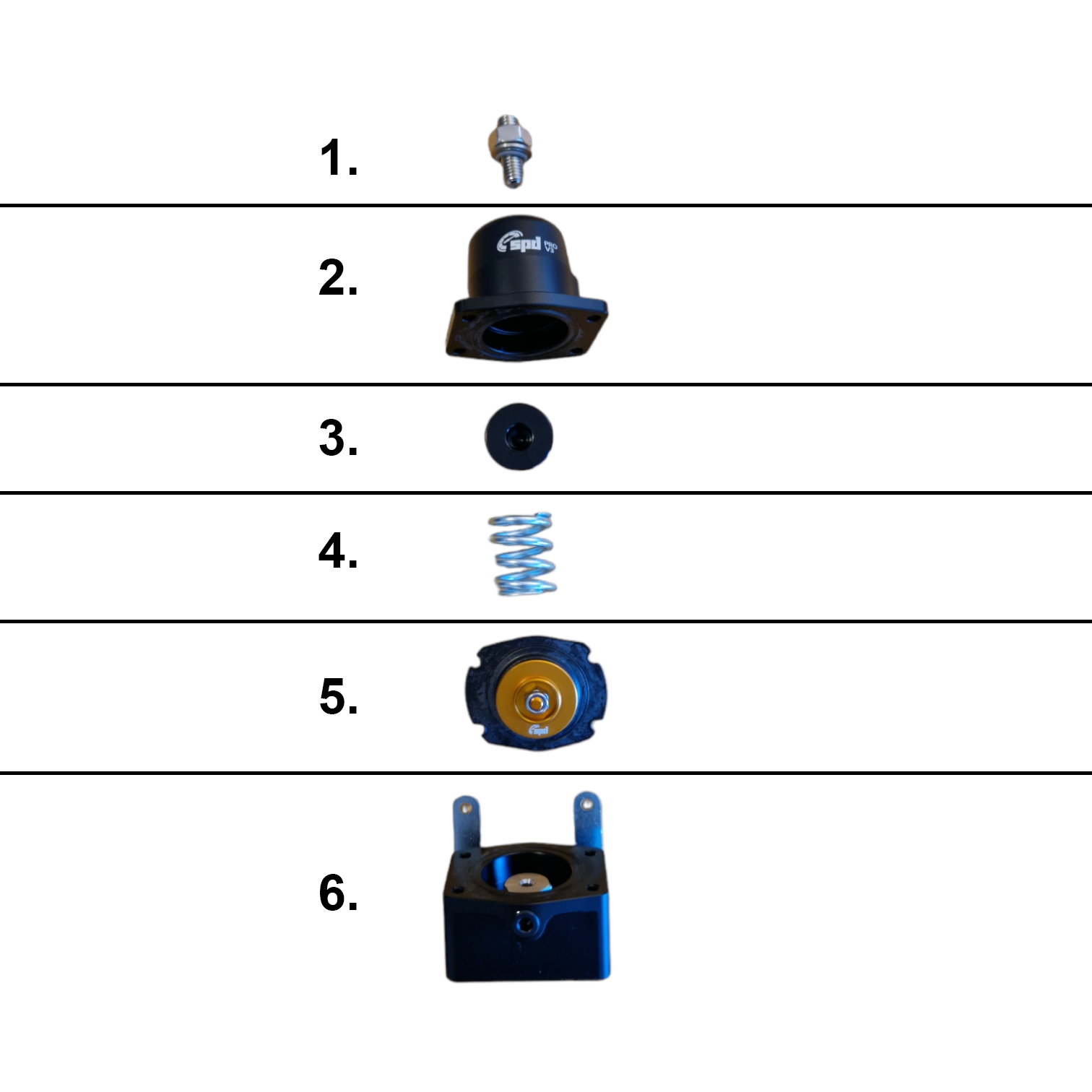

Picture 1

Picture 1

- Adjustment screw / Fuel pressure adjustment

- Top part fuel pressure regulator

- Upper spring seat

- Spring

- Diaphragm

- Bottom fuel pressure regulator

2 ▼

Connections

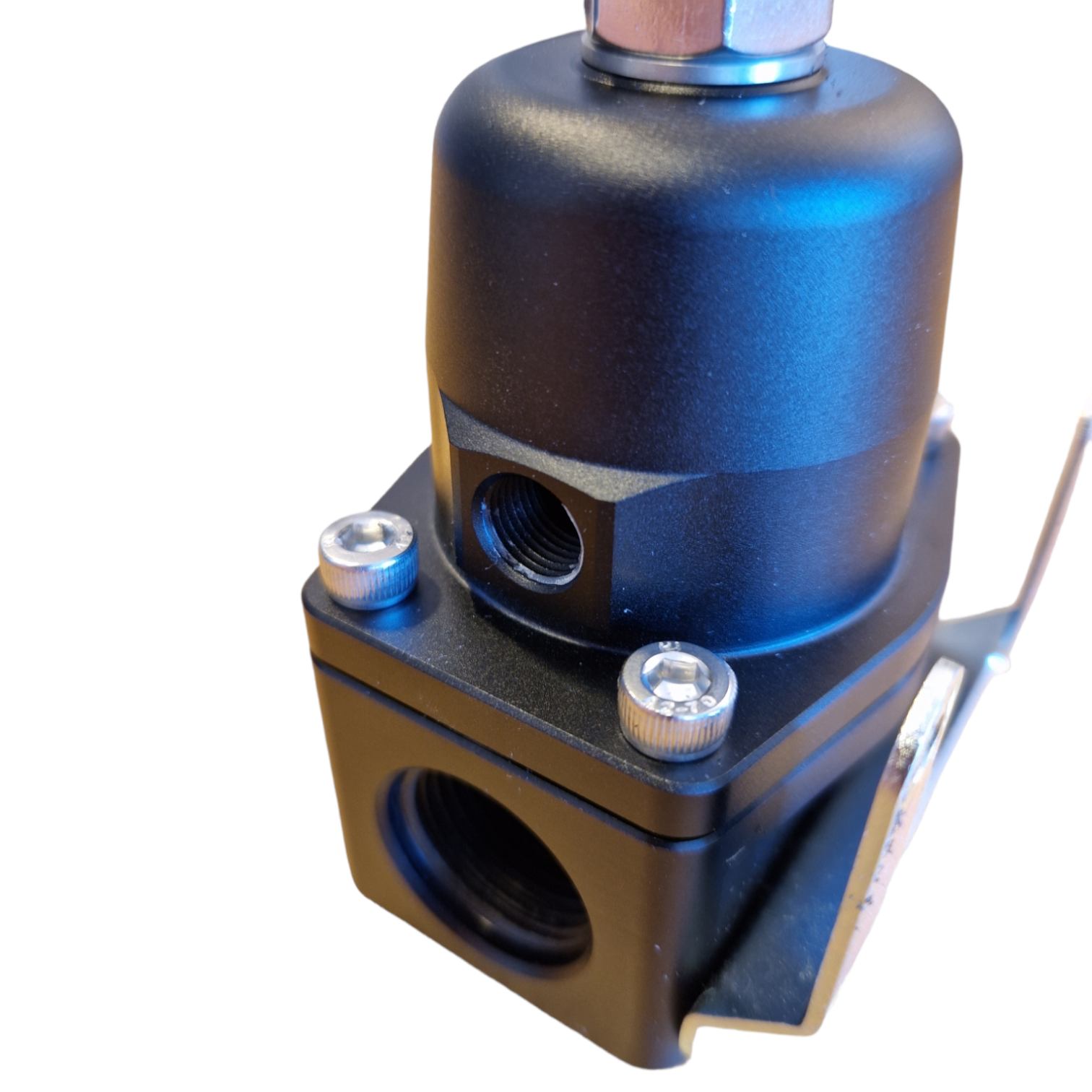

Picture 2

Picture 2

Inlet 1

If you have a fuel rail, only one input is used. The other input is plugged. It does not matter which input is used by Inlet 1 and Inlet 2.

Depending on the regulator, this can be a barb for hose connection or AN thread for O-ring adapter (ORB)

Picture 3

Inlet 2

If there are two inlets on your fuel pressure regulator, you can use two fuel rails from a V6 engine / V8 engine / V engine. Then both inlets from each fuel rail can be used. The fuel pressure regulator then splices two lines together into a return line similar to a Y-cross.

Depending on the regulator, this can be a barb for hose connection or AN thread for O-ring adapter (ORB)

Picture 4

Return / Outlet

Excess fuel passes out through the bottom port. This is led back to the fuel tank or the fuel catch tank if one is used.

The minimum size of this return hole determines how much a fuel pressure regulator max can flow.

Depending on the regulator, this can be a barb for hose connection or AN thread for O-ring adapter (ORB)

Picture 5

Adjustment screw / Fuel pressure adjustment

With this adjusting screw, the pressure on the spring in the regulator is adjusted. More preload = higher spring pressure = higher base fuel pressure.

Before adjustment, the locking nut must be released. After the pressure has been adjusted, the locking nut must be tightened again so that the pressure does not change.

Picture 6

Vacuum connection

This port has a 4/6mm vacuum hose and must be connected directly to the plenum on the intake without joints.

Nothing should disturb this and the hose should be included in the service schedule, as an incorrect reference signal from here will result in wrong fuel mixture.

Most often this is 1/8" -27 NPT thread but can also be a hose connection barb.

Picture 7

Sensor connection Pressure / Temp

Socket for external sensor to the fuel. Pressure or temperature can be measured here. Most often this is 1/8" -27 NPT thread.

3 ▼

Fuel pressure regulator adjustment

1. Start the engine.

2. Pull out the vacuum hose from the regulator and block the end of the vacuum hose so that the engine does not draw air. (Picture 6)

3. Adjust the spring pressure with the adjusting screw to the desired base pressure. Usually 3 bar. (Picture 5)

4. Put the vacuum hose back. (Picture 6)

Note. Your adjusted base pressure (usually 3 bar) minus the pressure now displayed is your engine's idle vacuum.

4 ▼

Quality

A malfunctioning fuel pressure regulator can cause serious damage to your engine. Therefore, it is important to choose a good regulator.

1. Choose a regulator with a durable diaphragm

2. The diaphragm must be compatible with your fuel

3. The return port must be dimensioned for your power output

5 ▼

Pressure drops when engine is turned off

This is perfectly normal if you have a high flow regulator. High flow = large return hole = poorer seal = fuel pressure drops when the engine is shut down.

Looking at an original fuel pressure regulator, the flow is low with a small hole. This provides a good seal and fuel pressure is maintained for a long time after engine shut down.

The material on the seat also determines how well the regulator seals, a plastic seat with a metal ball seals very well.

If you have bought a new aftermarket / Performance regulator, you can count on it to get a little better after driving for a while when the regulator has had time to wear in. It won't hold tight like an OEM regulator, but it will be better. Of course, how much better it gets can vary.

6 ▼

Fuel in vacuum hoses

When you find fuel in the regulator, it is most likely because the diaphragm in the regulator has broken. Therefore, step 4 (Quality) is important. Choose a good quality fuel pressure regulator.

If an original (used) fuel pressure regulator is used that has worked back and forth in one position for many years, there is a great risk that it will break if you change the fuel type, increase the boost pressure or anything else that affects the regulator movement pattern.

Aftermarket fuel pressure regulator that is adjustable and made for large pressure variations will eventually slowly lose its function if the diaphragm is not replaced at least once a year or at service.

Problems that arise when the diaphragm brakes are, in addition to incorrect fuel pressure, fuel in hoses, AND pressure sensors can get fuel in them and show wrong values or stop working altogether.

The membrane is a service part and must be changed at least once every season. Original FPR does not have replaceable menbrane.

7 ▼

Connecting the fuel pressure regulator

A fuel pressure regulator can be connected in different ways remaining the same function. Often there are 2 inlets (Picture 2 and 3) and 1 return/outlet (Picture 4).

Fuel pressure regulator after fuel rail

Most common is when the fuel pressure regulator is connected after a fuel rail. Then the pressure between the fuel pump and regulator is most safely adjusted when the fuel pressure regulator is placed close to the fuel rail. The vacuum line will also be short (close to engine) and there is less risk of problems.

Fuel pump -> Fuel filter -> Fuel rail -> Fuel pressure regulator -> Return to fuel tank.

Fuel pressure regulator before fuel rail / "Non return system"

This variant is usually called a returnless system when placing the FPR before the fuel rail. It is not true that it lacks a fuel return. This system has a fuel pressure regulator, which has a return. The regulator can be placed at the front of the fuel rail and the back of the fuel pump. Sometimes so close to the fuel pump that it is integrated with the fuel pump hanger. It is now called a non-return system, as there is no return line. The vacuum hose is now very long, and problems can arise.

Fuel pump -> Fuel pressure regulator (Return to fuel tank) -> Fuel filter -> Fuel rail

This type of regulator works like a normal regulator that is mounted before the fuel rail. This can also be replaced with a classic regulator, but new fuel lines must be drawn.

▼

▼

-

Fuel system

- Fuel system: Components and assembly

- Fuel system: Common problems

- Choose the correct fuel injector

- Check valve - Information

- Compare Fuel injectors

- Different Type of Fuels [Gasoline or Ethanol?]

- Different types of fuel systems

- Fuel catch tank / Fuel surge tank

- Fuel cell

- Fuel filter

- Fuel pressure regulator

- Fuel pump

- Fuel Pump Hanger - Information

- Fuel rail - Information

- Injector flow - Horsepower rating

- Injector size

- Tank ventilation / Roll over valve