Fuel system: Parts and assembly

With this information, you will be able to build a fuel system yourself. Whether it's for an standard car, a tuned car or a racing car. Speeding has built and helped with fuel systems for both street cars and winning race cars for over 10 years with very good results and now it is your turn to learn how to do it the best way.

We will cover all the parts to make you feel safe with your choices and how to connect and make them work together the best way.

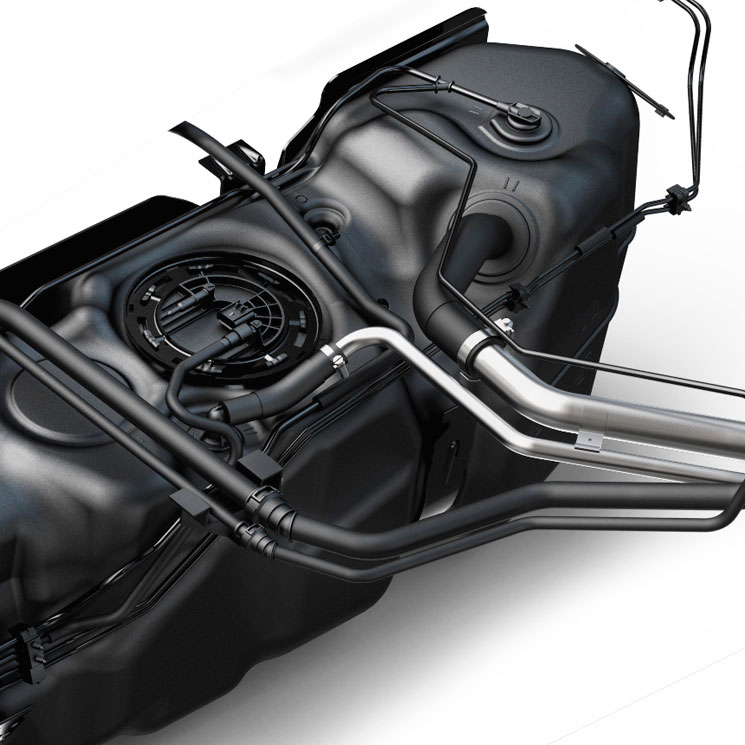

The fuel system looks like this:

- Fuel tank (Fuel cell)

- Fuel filler

- Roll over valve (Tank breather)

- Fuel pump

- Pre filter

- Check valve

- Fuel pump hanger

- Catch tank

- Fuel filter

- Fuel rail

- Fuel injectors

- Fuel pressure regulator (FPR)

- Y-cross/ Split

- Fittings and hose

When you read about different fuel parts below, you will feel safe with you choice of parts and you can overlook problems. This way you get a better and cheaper fuel system without trial and error.

1. Fuel tank / Fuel cell

A fuel tank must hold the fuel safely. It is mounted low and in the middle of the car. There you have a protected place with a low center of gravity.

This can be used to advantage if the car is to be tuned. It is really only if the original tank is not permitted according to regulations or if it has to be moved for constructional reasons that it is replaced with a so called fuel cell.

Original fuel tank usually has the fuel pump mounted in the tank in a so called fuel pump hanger. This can be converted to external fuel pumps, but then connections for this must be created, these are usually prepared on a aftermarket fuel cell.

Other connections that are located on a fuel tank and fuel cell are venting, refueling and sockets for fuel outlet / inlet. Inlet and outlet are located in the fuel pump hanger if the tank is equipped for internal fuel pumps.

The connections needed for a fuel tank to work: 1. Refueling 2. Fuel out 3. Fuel return 4. Tank venting

2. Fuel filler

The fuel filler is located well above the fuel level and are there for fuel refilling. When fuel is added the air inside the tank need to be evacuated. This is done through a tank ventilation hose. This hose is routed up to the fuel filler along with the fuel filler hose. This allow faster fueling.

The fuel filler have hose connections around 50mm diameter. the extra tank ventilation use to be around 10mm. Both use to be hose connections but other versions are used depending on manufacturer.

The connection to the tank for refueling is made for hose and hose clamp. If you use pipes, you can connect the tank and pipes with hose and hose clamp.

3. Roll over valve (Tank breather)

The tank breather must be mounted so that the fuel tank does contract (vacuum) when the fuel pump pumps out fuel. And so the tank does not swell when it is hot outside and gases expand. These are just two examples where the tank breather equalizing the pressure in the fuel tank.

OEM call this the EVAP system. Then the gases are led back to the engine intake by means of an electronic valve. This is because the system must be closed.

Tank venting on an aftermarket fuel cell is usually called a roll over valve. This is then the venting, but it only leads out the fuel vapors in the simplest way in the open air.

A roll over valve also works exactly as the name suggests. If the car ends up upside down in an accident, the fuel does not escape because the roll over valve closes the outlet when turned upside down.

The roll over valve must be mounted vertically to operate. A hose from the valve must be led to as high a point as possible above the level of the fuel tank. This is so that fuel is not pushed out at g-forces laterally.

4. Fuel pump

The fuel pump feed fuel from the fuel tank to the engine. It can be mounted in a tank or externally outside the tank. This is due to the design of the pump. An external fuel pump has threads on the inlet and outlet. An internal pump has a hose connection on the outlet and a quick connection to the pre-filter (inlet).

A high pressure pump for electronic injection works between about 2-9 bar while a low pressure pump for carburetors and TBI systems works up to about 1 bar.

GDI / FSI / Piezo injectors for direct injection have a mechanical fuel pump that sits on the engine and is driven by, for example, a camshaft. This type of mechanical fuel pump can deliver pressures of about 200-2000 bar and sometimes more.

Internal fuel pump = 8-9mm hose connection outlet, pre-filter is mounted directly to the inlet.

External fuel pump = Thread to inlet and outlet, pre-filter is fitted with hose to inlet.

5. Pre filter

When refueling, coarser dirt can enter the fuel tank. The pre-filter of the fuel pump prevents this from entering into the system.

Original, the pre-filter is often built into the fuel pump hanger. In the aftermarket, the pre-filter is mounted directly on the in-tank fuel pump. An external pump, on the other hand, has a thread on the inlet which means that the in-line pre-filter can be mounted in series. This is done by threading the filter directly on the fuel pump or using hose and fittings to connect them.

100-150 microns are used as pre-filters.

Internal fuel pump = Pre-filter is mounted directly to the inlet with a quick connection.

External fuel pump = The inlet has a thread = Pre-filter is threaded on directly or with hose and fittings.

6. Check valve

Original, the check valve prevents the fuel lines from being emptied. The fuel remains in the lines for a quick start.

Aftermarket check valves are not as good at maintaining the pressure afterwards, but they are made to flow better than the original check valves. When an engine is to be tuned, several fuel pumps can be used and if they start in steps, check valves are needed so that the fuel does not slip back through the pumps that is off.

Original = better seal = less flow = keeps the pressure up longer then aftermarket check valves.

Aftermarket = better flow = less seal = does not keep the pressure up as long as an oem check valves.

Original check valve usually has special connections and is rarely used for conversions.

Aftermarket check valves have standardized connections and can easily be used with other products.

7. Fuel pump hanger

Fuel pump hanger is a unit located in the fuel tank so that a fuel pump can be mounted in the fuel tank. This is the same principle on both OEM fuel tanks and the aftermarket fuel cell.

Original fuel pump hangers can also function a bit like a catch tank as the return fuel from the engine is recirculated here. Depending on the model, fuel level meters and sometimes also the fuel pressure regulator can be mounted here also.

Aftermarket fuel pump hangers can look different and often allow the installation of several fuel pumps. Some also have a built in catch tank, tank vent and fuel level sender.

Driving without a fuel pump hanger and instead using an external fuel pump is also common on rebuilt cars.

The connection of the fuel pump hanger to the fuel cell / fuel tank is model adapted. You use / rebuild the one that is already installed or if a ready made alternative is available to buy as an accessory.

8. Catch tank

An external fuel catch tank is not used standard (OEM). During heavy cornering / racing, the fuel in the fuel tank is pushed to the side, -away from the fuel pump. In this way, the fuel supply to the engine disappears.

To counteract this, the fuel is instead pumped to a catch tank that is filled up. Then another fuel pump pumps fuel to the engine from the catch tank.

Now there is always fuel in the catch tank at heavy cornering.

The catch tank can also be built into the fuel tank. But the same principle with two fuel pumps applies when one has to fill the catch tank and the other supplies the engine with fuel.

Fuel pumps can be located internally or externally in the catch tank.

Fuel path to engine:

Fuel tank> Catch tank> Engine.

The fuel's way back to the fuel tank:

Engine> Catch tank> Fuel tank.

Connections on a catch tank are usually at the top. These are threaded to be able to easily adapt connections.

Electrical connections are often available to allow internal fuel pumps to be used.

9. Fuel filter

A fuel filter is located between the fuel pump and the fuel injector. This filter prevents dirt from reaching the fuel injector.

Original fuel filters are often replaced with an aftermarket fuel filter if a car is tuned more as the flow will be higher.

The replaceable insert on an aftermarket fuel filter is made of a paper material or in stainless steel. Stainless steel is preferable as they last better and filter dirt just as well down to 10 microns.

10-30 microns are used as high pressure filters.

Fuel filters have one inlet and one outlet. Both are threaded so they can be easily connected to all possible applications.

Note the flow direction on the fuel filter.

10. Fuel rail

A Fuel rail distributes the fuel between the different injectors that are mounted. Original fuel rail is good enough for a lot of power. The reason for this being replaced is because connections are often odd and an OEM fuel pressure regulator is mounted directly on it as a restriction. Instead of rebuilding originals, this is instead replaced by an aftermarket fuel rail.

The internal size of the aftermarket fuel rail is usually 16-20mm to be able to distribute a lot of fuel between injectors.

An aftermarket fuel rail has one connection at each end for easy installation. Additional outlets may also be available for sensors and alternative connections. Threads for brackets are available unless model adapted brackets are bought.

11. Fuel injectors

Injectors are the part that finally injects fuel into the engine using the control system (ECU). This can also have a filter mounted in the top.

There are injectors for electronic injection (EFI) that are mounted on the intake before the valves. And there are injectors for GDI / FSI / Piezo (Direct Injection) that are mounted in the cylinder head down in the combustion chamber.

When tuning an engine, more fuel is needed. Therefore, larger injectors are mounted.

Top feed injectors (EFI) are mounted between the intake manifold and the fuel rail. The length of the injector can vary, but the length used before is the one usually used again.

Top feed injectors for European cars usually have 14mm O-rings.

Other top-fed injectors can have 11mm upper o-ring. There are also cases with 16mm lower o-ring.

12. Fuel pressure regulator (FPR)

An EFI fuel system wants a certain pressure e.g. 3 bar. to then increase the pressure linearly in parallel with the engine boost pressure. This is so that the fuel injector can supply enough fuel. A fuel pressure regulator takes care of adjusting this.

Original fuel pressure regulator is very precise for the standard working area. With a tuned engine that requires more fuel, the original fuel pressure regulator can probably not adjust this that well anymore.

Aftermarket fuel pressure regulator for EFi systems easily adjusts between 3-9 bar and sometimes more.

Threaded inlets / outlets are used for easy installation. There may be several inlets on a fuel pressure regulator so it can be used as a y-cross / split for V6 / V8 installations. Outlet / return port is located at the bottom.

13. Y-cross/ Split

A Y-cross / X-cross / split is simply used to divide several hoses or pipes.

If several fuel pumps are used or if you have a V-engine, a y-cross can be used connect these int one system / fuel line.

Aftermarket fuel pump hangers and fuel pressure regulators may have this built in already. eg 2-3 inlets and 1 outlet.

A split such as y-cross have threaded connections for easy mounting together with hose and fittings. There are also connections for sensors.

14. Fittings and hose

All components in a fuel system have a thread or hose connection. One for inlet and one for outlet at least. These fuel parts are connected with the help of hose and fittings.

Standard applications ofthen use a plastic hose that is heat crimped on connections. This is a very compact solution but nothing that can be done at home yourself. Therefore AN fittings and hose are used. With the help of these, all parts are easily connected together.

Do you want to use AN6 lines, for example? Simply adapt the products input / output to AN6 using adapters.

If you want to use classic 8mm hose and hose clamp, this also works well. Simply adapt the products input / output to the 8mm hose connection using adapters.

When you know what type of hose you should have: Adapt all products with adapters so this size can be used throughout the system.

▼

▼

-

Fuel system

- Fuel system: Components and assembly

- Fuel system: Common problems

- Choose the correct fuel injector

- Check valve - Information

- Compare Fuel injectors

- Different Type of Fuels [Gasoline or Ethanol?]

- Different types of fuel systems

- Fuel catch tank / Fuel surge tank

- Fuel cell

- Fuel filter

- Fuel pressure regulator

- Fuel pump

- Fuel Pump Hanger - Information

- Fuel rail - Information

- Injector flow - Horsepower rating

- Injector size

- Tank ventilation / Roll over valve