Engine and clutch Balancing

Crankshaft and clutch balancing. Something that is just as important for the engine power as a bigger turbocharger..

- What is balancing?

- Different expressions when balancing

- Clutch balancing

- Problems

- Compare flywheels

1 ▼

What is balancing?

To balance engine parts, they must be rapidly rotated while measuring any imbalance. If adjustments are needed, weight can be added or removed. It's important to balance parts in the same place and machine to ensure accuracy.

Example, the crankshaft and flywheel should be balanced together. Balancing parts separately and then assembling them can lead to poor results. Both static and dynamic imbalance can reduce engine power and cause problems at high rpm.

2 ▼

Different expressions when balancing

Dynamic

Dynamic balancing is done by rapidly rotating parts and measuring imbalance. Adjustments can be made by removing or adding weight, then re-measuring and seeing if the imbalance is corrected.

Static

Static balancing is done by placing the part centred on an axis. Now it should not tip over in any direction. Adjustments can be made by removing or adding weight, then re-measuring and seeing if the imbalance is corrected.

Horizontal

Horizontal balancing = Made in factory = The part is balanced horizontally.

Vertical

Vertical balancing = Individual fine-tuning = The part is balanced vertically

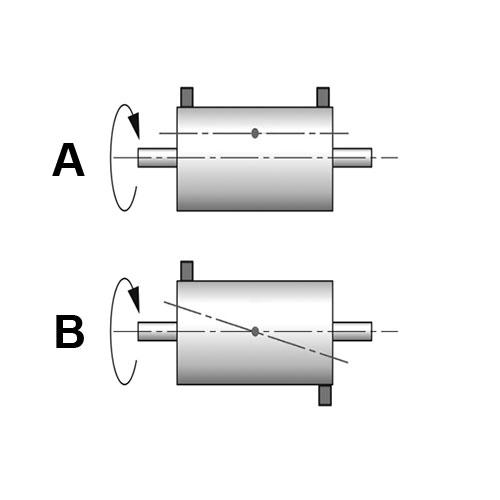

Static vs. Dynamic balancing

Here we see an example of how Static and dynamic imbalance works.

Image A illustrates static imbalance.

Image B illustrates dynamic imbalance.

One should not compare vertical and horizontal balancing as they are two different types of balancing

3 ▼

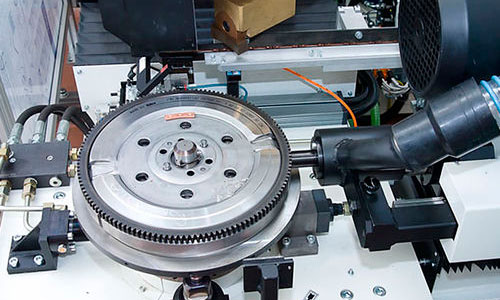

Clutch balancing

Flywheel factories typically use horizontal balancing without a counterweight to increase production efficiency. This balancing type is generally within 3 grams but may vary between productions. While dual-mass flywheels with internal mechanics and more imbalance are often used, they can cause issues in motorsport and tuning. In these cases, a single-mass flywheel is used with a balancing machine, where a crankshaft acts as a counterweight. This method allows for fine-tuning of the balancing, even for the clutch's pressure plate.

To balance a flywheel for performance/motorsport, it is adjusted using dynamic balancing in a vertical position with a counterweight. This process requires a well-balanced counterweight, regardless of whether it was used during the factory balancing process.

All measuring tools must be calibrated according to the manufacturer's recommendations.

Make sure the crankshaft and flywheel are balanced together.

4 ▼

Problems

Split flywheel

Several parts make it more difficult to balance and place high demands on the balancing done.

The balancin

Make sure to use the same machine when balancing so that this does not become a deviating factor as the results may differ

Counterweight

Make sure to use the same counterweight if one balancing is to be compared against another.

Measured values

A flywheel that is balanced to "0" in one place and a crankshaft that is "0" from another place will not be 0 together. Both machine, working method and many other factors can differ. These must be balanced together.